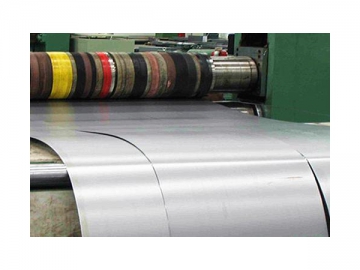

(4.0- 16.0)mm×2200mm Slitting Line

This thick plate slitting line, also called a metal coil slitter, is used to slit thick steel master coil into smaller baby coils. The thick coil slitting line is composed of a coil-loading car, double mandrel big-load uncoiler, portal style coil-head guide, press and shovel equipment, double roller pinching feeder, five-roller leveler, end-cutter, roll table, central aligner, disc slitter, scrap winder, coil accumulator, pre-separator & tensioner, portal style coils-separator and presser, recoiler, coil unloading car, hydraulic control system, and electric control system.

Different model capacities:Strip thickness: (3~12) mm, (4-16) mm, (5~20) mm; Strip width: 500-1800mm, 800~2000mm or 1000~2200mm.

GalleryCoil-loading → Double-mandrel uncoiling → Coil-end-feeding & shoveling → Double-roller pinch feeding/five-roller leveling → End-cutting → Coil Accumulator 1 → Strip-aligning → Disk shearing → Scrap reeling → Coil Accumulator 2 → Pre-separator / Tensioner → Separating, Recoiling → Coil-discharging → Hydraulic control → Electric control

Technical Parameters| Raw Material | Hot/Cold formed steel, Galvanized steel, ST37, ST52, S235, S355 |

| Yield Strength | ≦ 235MPa |

| Material Thickness | 3.0~20.0mm |

| Slitting Width | 800~2200mm |

| Slitting Motor | 200KW DC Motor |

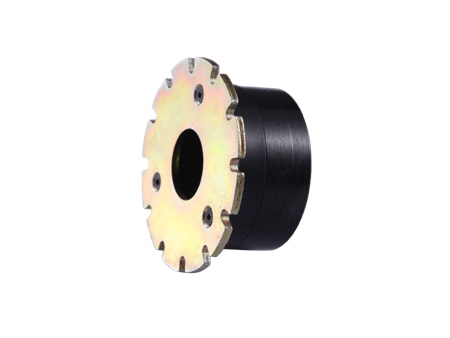

| Cutter Shaft | 360 x 2250mm |

| Slitting Strip | Max.20 strips |

| Recoiler Motor | 250kW DC |

| Line Speed | Max.40m/min |

| Coil Weight | 40,000kg |

| Min. Slit Width | 100mm |

| Total Power | 480kW |

| Model | Thickness | Width | Weight | Slit Width | Max. Slitting Speed |

| ZJ-12 x 1800 | 3-12mm | 600-1800mm | ≦ 35T | ≧ 60mm | 50m/min |

| ZJ-16 x 2200 | 4-16mm | 800-2200mm | ≦ 40T | ≧ 100mm | 40m/min |

| ZJ-20 x 2000 | 5-20mm | 800-2000mm | ≦ 40T | ≧ 100mm | 30m/min |

Each production line is strictly designed and made according to customer requirements, and we are dedicated to offering production lines that best fit customer needs. Please do not hesitate to contact us for more information.

Advantages & Characteristics- Strength and solidity is extremely important for thick sheet slitting machines. We take the metal coil slitter’s structural design and material usage into consideration during the design stage. For example, a portal style coil-head guide and press, a dual body scrap reeler, a five roller tensioner for recoiling, and a portal style coil pressing and separating bracket are all parts installed on the machine to ensure a high performance operation.

- The double cone-mandrel decoiler is capable of not only bearing coils as large as 35 to 40T, but also makes it easy to load those coilers into a decoiler.

- The coil-loading car has a support platform with two rotatable rollers at the edges. One roller solidly supports the large coil, while the other is loading a coil onto the double cone decoiler. Double rollers on the coil car platform rotate synchronously with the decoiling mandrel.

- The strength of all rollers and shafts increase with the steel strip thickness.

- Dual-body scrap winders are driven by two torque motors and two speed reducers.

- The recoiling tensioner of the metal coil slitter uses a solid five-roller tensioning structure, thus providing a stable and even tension for recoiling.

- The coils pusher is installed on the recoiler in order to push coils out while discharging slit coils.

- AC motors and speed reducers drive the pinch-feeder & five-roller leveler and five-roller tensioner, while DC motors & speed reducers drive the slitter and recoiler.

- The coil slitting machine's electric control is a Eurotherm 590 speed controller PLC control.