Electronic Pressure Comparator HS318L

Product Description

The HS318L electronic pressure comparator is an excellent pressure source designed for comparative calibration purposes. Depending on servo valve control, pressure is quickly stabilized and remains unchanged after stabilizing. With an external air source, it easily generates pressure up to 600bar. An F-adjust valve provides precise adjustment of pressure, and the minimum adjustable pressure value is 1kPa. In addition, the gauge comparator ensures fast pressure generation. Only 5 seconds are needed from zero to full range.

Pressure Comparator Features

1. A transparent oil cup is convenient for observation of working medium and it can be easily removed for cleaning.

2. 5 pressure ports with standard M20*1.5 quick connectors allow simultaneous connection of 4 pressure gauges under test, making calibration more efficient and time saving.

3. It is quite easy to operate. Only one finger is needed to generate pressure from zero to full range.

4. Air circuit features rugged and reinforced construction. This leads to high sealing performance and more stable pressure generation.

5. Unique priming function widens the calibration range and successfully handles the difficulties in calibration of several gauges.

Technical Specifications

Pressure range: 0~600bar

Working medium: 25#transformer oil

Materials: Steel for body; stainless steel for outputs

Pressure connection: M20*1.5 female

Dimensions: 730Lx350Wx250H (mm)

Weight: 26.5kg

Packaging: plywood box

Working environment: Laboratory

Applications

The electronic pressure comparator is suitable for mass and repeat calibration needs in power, chemical, oil, metallurgy, metering and other industries. It provides the accuracy, stability, efficiency and capability you need to calibrate pressure gauges, transmitters, switches and other pressure instruments by means of comparative measurements.

| Huaxin's HS318L Electronic Pressure Comparator | Similar comparators from our competitors | |

| Pressure generation system and sealing stability | 1) With the most effort saving pressure generation system in the industry; 2) External air source; 3) Time for pressure generation to 60mPa s less than 10s; Time for stable pressure is less than 5s; 4) High stability; 5) Superior servo valve for pressure control; 6) Strict pressure tight test and aging test before delivery | Stand-alone priming pump and manual pressure adjustment; Not easy to operate and not accurate pressure control |

| Filtration system | 1) Multi-function oil cup that features one-piece design with the shut-off valve; 2) Oil cup comes with filtration system, making it easier to clean and change; 3) No liquid level difference | No such function |

| Priming system | Multi-angle rotation priming pump can be operated at different angles according to personal habits | No such function |

| Safety | 1) External air compressor with pressure control system; 0.6mPa air pressure from the air source is enough to generate pressure to 60mPa; 2) Over pressure protection function for the gauges | Independent handpump for system priming likely results in damage of gauges; this is dangerous |

| Airtight performance | 1)Quick connection of air source ensures excellent airtight performance combined with high pressure control accuracy (hydraulic pressure<1kPa); 2) Rugged and reinforced air circuit allows for easy maintenance; | Manual pressure adjustment is not likely to reach the highest accuracy; Screw seal gives rise to many leakage points and is not good for maintenance. |

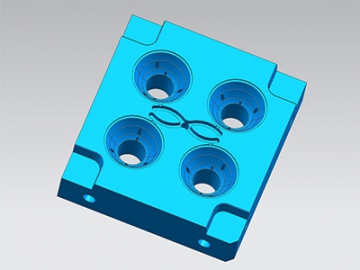

Components of the Electronic Pressure Comparator

1. Hand Pump

Uplift the hand pump and press it down repeatedly to mobilize the piston for system priming

2. Ventilation Nut

The inlet for charging of 25# transformer oil; turn it anti-clockwise to add or replace oil

3. Oil Cup

Transparent oil cup for easy observation of working medium and it can be easily removed for cleaning

4. Pressure Ports (Outputs)

There are five pressure ports. One is designed for reference gauge and the others for gauges under test.

5. Pressure Regulator

After system priming, turn the regulator clockwise toward " " to get higher pressure, and turn it anti-clockwise toward "-" to decrease pressure.

6. Switching

With 3 selectable positions-"Zero, Stop, Booster"

7. Shut-off Valve 1

It is used for corresponding output. Turn it clockwise to shut off the connection between the output and the pressure calibration system.

8. Shut-off Valve 2

Have to close it before pressure generation (clockwise). Open it to release the pressure (anti-clockwise).

9. Plug

Tighten it up when not in use to prevent dust and other matters.