Full Color Flexo Printing Press

Request a Quote

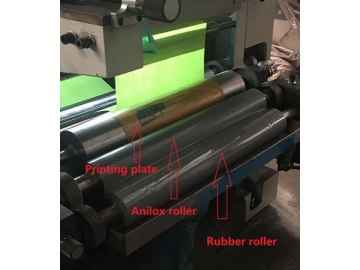

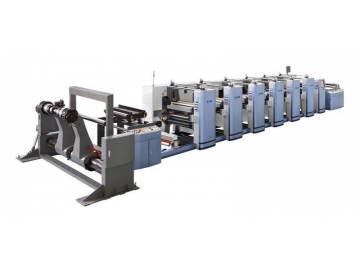

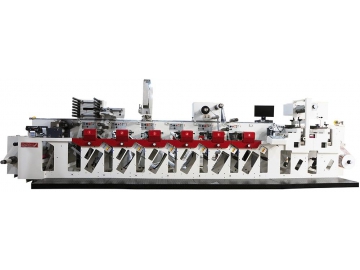

The YTG600-1300 flexographic press is equipped with outstanding components including a ceramic anilox roller, closed doctor blade, and Servo EPC device. It is suitable for clients who have strict demands on printing quality and mass production.

This machine can print plastic film like BOPP, PET, PE, PVC, CPP, nylon, paper, non-woven, PP woven, aluminum foil.

We can make the width from 600mm-2000mm.Color from 2-10 colors.

| Model | YTG6800 | YTG61000 |

| Max material width | 800 mm | 1000mm |

| Max printing width | 760 mm | 960mm |

| Printing length | 200-1000mm | 200-1000mm |

| Printing color | 6 color | 6 color |

| Max diameter of unwind and rewind | 600 mm | 600 mm |

| Max Speed | 100m/min | 100m/min |

| Thickness of plate (Including Two-sided Glue Paper) | 2.38 mm(Or u choose) | 2.38 mm(Or u choose) |

| Total Power | 34 kw | 38KW |

| Weight | 5500kg | 6000KG |

| Dimension | 5800×2800×2900 mm | 5800×3000×2900 mm |

| Main motor | 5.5KW | 5.5KW |

- Both rewinding and unwinding systems are equipped with an automatic tension controller.

- Servo EPC device is controlled by servo motor.

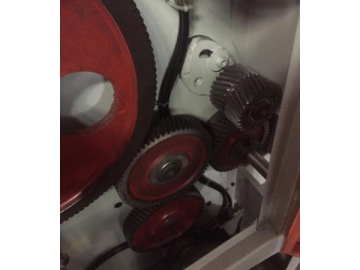

- The ascending and descending of the roller is under pneumatic control. The ink will be stirred automatically when the roller ascends.

- This industrial flexographic press is equipped with a cooling system which prevents the printings from sticking together.

- This machine is equipped with a 360°continuous adjustable register system.

- Torque servo can adapt to different printing speed.

- When the printing plate roll descends, distributing motor stops rotating automatically. When the roll ascends, the distributing motor starts rotating automatically.

- The length of printing can be set on the console panel. The machine stops operating automatically whenever the printing length reach the set value or the material is broken.

- This industrial flexographic press is capable of reverse printing.

Related products

Send Message

Most Recent

More

Other Products

Videos