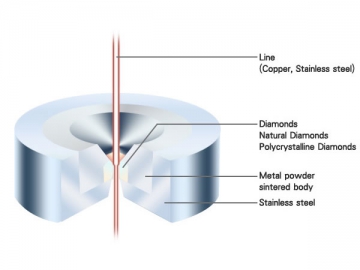

PCD Die Blanks (for Wire Drawing)

The PCD die blank has polycrystalline diamond grits exposed on its surface, and is made using a sintering process, under high temperature and pressure conditions. The metal catalyst, or bonding material, used in the sintering process is cobalt, which provides the base material upon which synthetic diamond powder can form a firm bond with the wire drawing die surface.

Features of the PCD Die Blank

Our PCD die blanks have a number of advantages, including high abrasion resistance, mechanical strength, and excellent thermal conductivity.

PCD wire drawing dies are also reliable choices when it comes to a variety of wires, as they offer stability and wear resistance.

PCD Blank Uses

PCD blanks are commonly used to make wire drawing dies for drawing wires made of stainless steel, copper, tungsten, molybdenum, nickel and more.

| ADDMA Code | Product NO. | Product Dimensions | Average Grain Size (um) | Max. Die Recommended (mm) | |||||||

| Φd | ΦD | T | 1 | 2 | 5 | 10 | 25 | 50 | |||

| D6 | | 2.5±0.2 | 1.0 0.2 | √ | √ | √ | √ | - | 0.4 | ||

| D12 | | 3.2±0.2 | 1.5 0.2 | √ | √ | √ | √ | √ | - | 1.0 | |

| D15 | | 5.2±0.2 | 2.5 0.2 | - | √ | √ | √ | √ | √ | 1.5 | |

| D18 | | 5.2±0.2 | 3.5 0.2 | - | √ | √ | √ | √ | √ | 2.0 | |

| D6 | | 2.5±0.2 | 1.0 0.2 | √ | √ | √ | √ | √ | - | 0.4 | |

| D6 | | 3.1±0.2 | 1.0 0.2 | √ | √ | √ | √ | √ | - | 0.5 | |

| D12 | | 3.1±0.2 | 1.5 0.2 | √ | √ | √ | √ | √ | - | 1.0 | |

| D15 | | 5.2±0.2 | 2.5 0.2 | - | √ | √ | √ | √ | √ | 1.5 | |

| D18 | | 5.2±0.2 | 3.5 0.2 | - | √ | √ | √ | √ | √ | 2.0 | |

| D21 | | 7.0±0.2 | 4.0 0.2 | - | √ | √ | √ | √ | √ | 3.0 | |

| D24 | | 9.8±0.2 | 5.3 2 | - | √ | √ | √ | √ | √ | 4.0 | |

| ADDMA Code | Product NO. | Product Dimensions | Average Grain Size (um) | Max. Die Recommended (mm) | |||||||

| Φd | ΦD | T | 1 | 2 | 5 | 10 | 25 | 50 | |||

| D12 | | 4.0±0.2 | 8.12±0.13 | 1.5 0.2 | - | √ | √ | √ | √ | √ | 1.0 |

| D15 | | 4.0±0.2 | 8.12±0.13 | 2.3 0.2 | - | √ | √ | √ | √ | √ | 1.8 |

| D18 | | 4.0±0.2 | 8.12±0.13 | 2.9 0.2 | - | √ | √ | √ | √ | √ | 2.3 |

| D21 | | 7.0±0.2 | 13.65±0.13 | 4.0 0.2 | - | - | √ | √ | √ | √ | 3.5 |

| D24 | | 7.0±0.2 | 13.65±0.13 | 5.2 0.2 | - | - | √ | √ | √ | √ | 4.6 |

| D27 | | 12.9±0.2 | 24.13±0.25 | 8.7±0.25 | - | - | - | √ | √ | √ | 5.8 |

| D30 | | 12.9±0.2 | 24.13±0.25 | 12.0±0.25 | - | - | - | √ | √ | √ | 7.6 |

| D31 | | 15.2±0.2 | 26.6±0.25 | 12.0±0.25 | - | - | - | - | √ | √ | 9.0 |

| D33 | | 15.2±0.2 | 26.6±0.25 | 15.0±0.50 | - | - | - | - | √ | √ | 10.0 |

| D33 | | 18.5±0.2 | 29.0±0.25 | 15.0±0.50 | - | - | - | - | √ | √ | 11.0 |

| D33 | | 18.5±0.2 | 29.0±0.25 | 18.0±0.50 | - | - | - | - | √ | √ | 12.0 |

.jpg)