Advantages of 3D printing

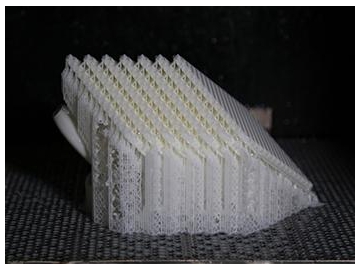

The thickness of each layer in stereolithography is very thin (0.05 to 0.10mm). With a fine laser beam, prototypes with a truly realistic finish and complex geometric shapes can be produced.

Although the materials are replaced with resins, the parts manufactured using stereolithography have a good surface quality.

The surface of the prototype created from 3D printing is smooth and clean.

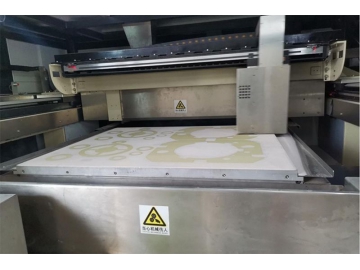

High-definition small widgets or larger parts with dimensions up to 2 meters can be printed via 3D printing with guaranteed precision.

It only takes about 2 days for you to receive your parts if using 3D printing because work can begin immediately upon receipt of drawings. It also features lower costs than other methods, as there is no need to produce a mold for production.

If you are looking for 3D printing service, kindly follow here for more info.