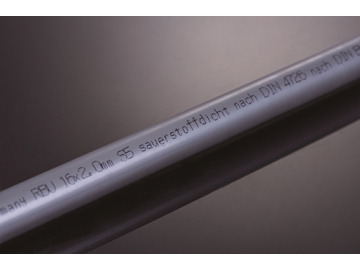

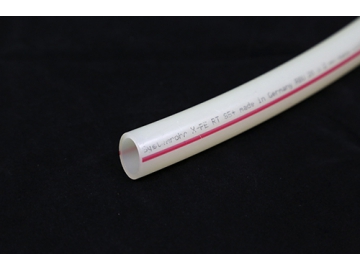

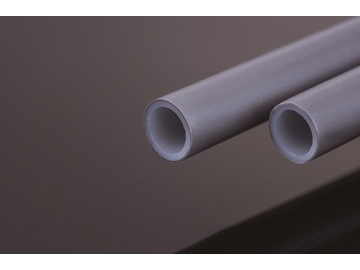

PE-RT Pipe

The PE-RT pipe is also called an underfloor heating pipe, and often used for heating systems and the hot water systems. The 5 layer PE-RT pipe produced by the Heim-Weh-GmbH has an outstanding UV-light resistance and oxygen impermeable performance, which can effectively inhibit the survival of microbes in the pipe system, and can also obstruct oxygen permeating into the pipe system, thus preventing the metal parts against corrosion and rust in the heating system and extending the pipe system service life.

- ISO 14001 Environmental Management System Certification

- ISO 9001 Quality Management System Certification

- Aenor Certification

- WRAS Product Approval Certification

- Certificate of Conformity

- SKZ Certificate

- DVGW (German Technical and Scientific Association for Gas and Water)certificate

- KIWA Certificate

5 layer structure

5 layer structure

EVOH oxygen barrier layer

EVOH adhesive

EVOH adhesive

PE-RT inner layer

PE-RT outer layer PPR raw materials supplier: Borealis

PPR raw materials supplier: Borealis

Use of lead-free environmentally friendly copper

Made in Germany

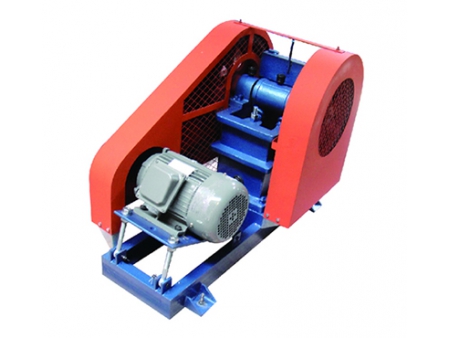

Injection molding process

| Properties | Unit | Data | |

| Physical properties | Density | g/cm3 | 0.94 |

| Hardness | -- | 61 | |

| Thermophysicalproperties | Linear expansion coefficient | m/(m·k) | 1.10-4 |

| Thermal conductivity | W/(m·k) | 0.4 | |

| Vicat Softening Temperature | ℃ | 124 | |

| Mechanical properties | Yield strength | MPa | 18 |

| Tensile strength | MPa | 39 | |

| Elongation at break | % | 800 | |

| Elastic modulus | MPa | 650 | |

For floor heating, there are five kinds of PE-RT pipes: Φ16,Φ20, Φ25,Φ32, Φ40. On the basis of their wall thickness, they are divided into:

dn20×2.0, dn25×2.3, dn32×2.9, dn40×3.7

dn16×2.0, dn20×2.3, dn25×2.8, dn32×3.6, dn40×4.5

- The PE-RT pipe has a dual effect of the UV-light resistance and oxygen barrier.

- The PE-RT pipe has an excellent thermal stability and can withstand long term pressure. Under a working temperature of 70℃ and a pressure of 0.4Mpa, the pipe can be safely used for more than 50 years.

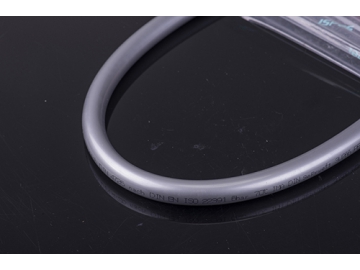

- The PE-RT pipe has an excellent flexibility, which makes it convenient and economical. The bending radius of the PE-RT pipe is small (Rn=5D) and doesn't rebound after bending. This makes it ideal for construction usage, and stress on bending parts is quickly relaxed, thus avoiding damage to the sinuosity caused by the stress concentration while servicing.

- The PE-RT pipe has an excellent impact resistance and high security, and its low temperature brittleness temperature is -70 °C, so that the PE-RT pipe can be transported and constructed in low temperature environment. Its ability to resist external force is much higher than that of other pipes, and does not need to be heated in order to bend.

- A heat fusion joining is available for the PE-RT pipe to make the product easy to install and repair. In the underfloor heating plumbing system, if the system is damaged due to an external force, the PE-RT pipe can be repaired using a heat fusion, which is more convenient, faster and safer.

- The PE-RT pipe can be produced without crosslinking process and controlling crosslinking degree and evenness. The PE-RT pipe has less production processes and an overall, even wall thickness.

| Melt flow index (g/10mm) | Density (g/cm3) | Compressive stress (MPa) | Tensile stress (MPa) | Elongation at break(%) | BrinellHardness (N/mm2) | Notch impact test (KJ/m2) | Vicatsoftening temperature (℃) | Melting range (℃) | Linear expansion coefficient (1/k) | Thermal conductivity (W/m·k) | Longitudinal shrinkage (%) | |

| Testing value | 0.3 | 0.898 | 25 | 850 | >50 | 48 | 130(10N) 61(50N) | 150-160 | 1.5x10(-4) | 0.24 | < 2 | |

| Testing standard | ISO1133 condition 12 | ISO1183 | ISO527/1.2 | ISO527/1.2 | ISO37 | ISO2039/1 | ISO179/1eu | ISO306/A-B | DSC | DIN53752 | DIN52612 | GBT6671- 2001-B |

| Testing condition | 230℃/ 2.16kg | +23℃ | 50mm/min | 50mm/min | 132N/30s | 23 0 -10℃ | 10N 50N | 135±2℃ |

The excellent thermal stability and purity of PE-RT materials are two of the properties of this material. The PE-RT material's physical and chemical properties are very suitable for potable water and heating. More importantly, the material's good melting and heat fusible properties achieve a permanent integral connection.

- Mark the insertion of the pipe. (Equal to the insertion depth of the joint)

- The surface of pipes and joints should be stable, clean and oil-free.

- Heat the entire insertion depth, including pipes and joints in the welding tool.

- Connect the pipe and joint

- When the heating time completed, smoothly and evenly push the pipe into the joint to form a firm and perfect combination.