Roll Forming Machine (for Roof Panel and Wall Panel)

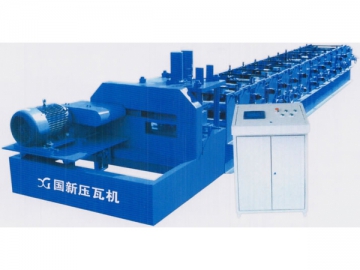

At Guoxin, we offer a wide selection of roll forming machines for roof panels and wall panels according to the size and thickness of color steel sheets. The profiles rolled by our roof panel forming machine and wall panel forming machine feature high durability while providing a gorgeous appearance. As a major Chinese roll former maker, we guarantee customers perfect after-sales services and offer technical support.

Our roll forming machine for wall panels employs a DVP14ES computer that features an electrical control system with a text screen and fully automatic fixed length cutting system for ease of operation and higher efficiency. This sheet metal equipment can make color steel sheets into panels in various corrugation styles which are used for both industrial and civil purposes. For example, the panels are suitable for roofing and walling.

Technical Parameters

| Dimension (L×W×H) | 6000mm×1300mm×950mm |

| Shaft | Dia.:70mm; Material: 45# steel |

| Roller | Made of 45# steel by forging and hard chrome plating |

| Driving parts | Chain wheel, Chains |

| Motor power | 3Kw |

| Forming rows | 10 rows |

| Motor of hydraulic power pack | 3Kw |

| Shearing die | Gr12 |

| Forming speed | 8-10m/min |

| Thickness | 0.2-0.7mm |

| Width | 1000m |

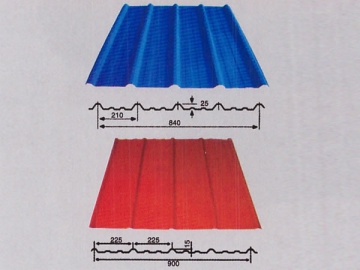

Guoxin has over 20 years of experience in the manufacturing of roll forming solutions for the steel construction industry. Our 840 roof panel roll forming machine can produce metal roofing tiles in different appearances with high product yields. For instance, the panel roll fomer can make 840 roofing tiles and 840 glazed roofing tiles at the same time.

It is a double deck roll former which comes with a two-in-one design, saving floor area, reducing cost and ensuring convenient transportation.

Technical Parameters

| Dimension (L×W×H) | 6400mm×1300mm×950mm |

| Shaft | Dia.:70mm; Material: 45# steel |

| Roller | Made of 45# steel by forging and hard chrome plating |

| Driving parts | Chain wheel, Chains |

| Motor power | 3KW |

| Forming rows | 11 rows |

| Motor of hydraulic power pack | 3KW |

| Shearing die | Gr12 |

| Forming speed | 8-10m/min |

| Thickness | 0.2-0.7mm |

| Width | 1000m |

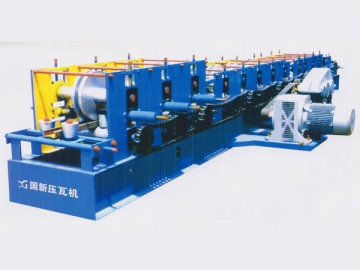

This roll forming machine can manufacture 900 type steel wall panels that differ from the traditional ones in installation methods. The traditional wall panels are jointed using screws while the 900 type panels are installed by means of 45° snaps, ensuring better water resistance.

Features of 900 Steel Wall Panels

High Intensity: the metal wall panels are made of high strength sheet steel (tensile strength: 5600KG/CM) , offering best-in-class design and roll forming process, thus providing ultra-high intensity.

Fire Resistance: the surface material and thermal insulation material of the wall panels are non-combustible materials, completely meeting fire safety rules.

Easy Installation:The wall panels made by our roll forming machine are light weight. They can be jointed to each other and cut to your specifications. Therefore, it is convenient to install, greatly improving efficiency.

Long Service Life:Studies and practices show that color steel panels with special coating can generally serve for 10-15 years. Their lifespan can reach over 35 years if you coat them with anti-corrosion paint every other 10 years after that.

Technical Parameters of Panels

| Wall panels model | 15-225-900 |

| Effective width (mm) | 900 |

| Developed width (mm) | 1000 |

| Corrugation height (mm) | 15 |

| Thickness (mm) | 0.3-0.8 |

| Driving parts | Chain wheel, chains |

| Shearing tool | Gr12 |

| Applications | Wall panels as well as roof panels; Suitable for large and medium size industrial and civil buildings such as workshops, locomotive sheds, hangars, gyms, exhibition halls, theaters, etc. |

This panel roll former can make 750 type roof panels that are elegant and stylish, and offer uniform corrugation and high durability. This metalworking machine provides perfect solutions for manufacturing roofing tiles of various workshops and warehouses, ensuring high strength and outstanding resistance to water, wind, and fire. Used with an arch camber machine, they can be used to make arched roofs without beams.

Technical Parameters

| Dimensions (L×W×H) | 5100mm × 1400mm × 1000mm |

| Electrical control system | Industrial PC, PLC, variable frequency control |

| Motor power | 3Kw |

| Speed | 0-9m/min |

| Panel purpose | Roof panel |

| Panel thickness | 0.25-0.8mm |

| Panel developed width | 1000mm |

The roll forming machine for 850mm corrugated roof and wall panels is composed of a roll former, PLC control system, shearing equipment, and a hydraulic power unit. It can produce profiles that have light weight, high intensity, great bearing capacity and excellent shock resistance for high rise steel structure buildings.

Technical Parameters of Panels

| Model | 13-65-850 |

| Effective width (mm) | 850 |

| Developed width (mm) | 1000 |

| Corrugation height (mm) | 13 |

| Corrugation distance( mm) | 65 |

| Purposes | Roof panels, wall panels |

Steel roof panels made by this roll forming machinery can handle high usage and great intensity. It uses a fully automatic fixed length cutting system, ensuring high production automation.

Technical Parameters

| Dimensions (L×W×H) | 6400mm × 1300mm × 950mm |

| Shaft | Dia.:70mm; Material: 45# high grade steel |

| Roller | Made of 45# high grade steel by forging and hard chrome plating |

| Driving parts | Chain wheel, Chains |

| Motor power | 3Kw |

| Forming rows | 11 rows |

| Motor of hydraulic power pack | 3Kw |

| Shearing die | Gr12 |

| Forming speed | 8-10m/min |