Swage Terminals

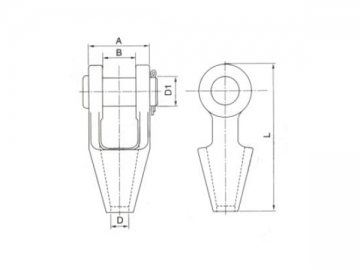

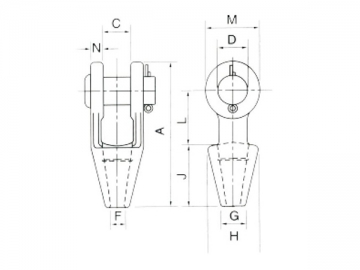

Junwei offers a wide range of rigging accessories and wire rope fittings. Within the range we offer high quality swage terminals such as swage eyes and swage forks. They are available in open and close types, and are made of high quality carbon steel rods by cold forging process. You can choose the right swage terminal ends according to the strength of wire ropes. If required, our friendly experts are glad to offer advice.

Features of the Swage Terminals

1. In virtue of swaging process, the wire rope terminal comes with consistent size, with end size slightly larger than the eye or fork size.

2. Spheroidizing annealing process is used to control hardness.

3. After swaging, labeling on the swage terminal will not generate cracks.

4. It has obtained US patents (Patent No.: 5, 152, 630) and patents of other countries.

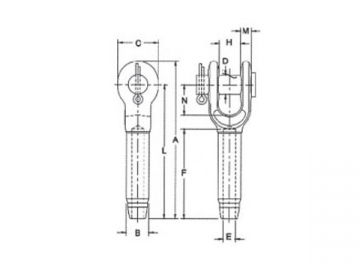

The S-501 swage terminal is recommended to be used on 6×19 or 6×37, IPS or XIP, RRL, FC or WRC wire ropes. According to the standards of ANSI B30.9, all wire rope slings that are used with the swage eye or for terminal should go through a tensile test.

| Wire rope diameter (mm) | Weight each (kg) | A | B | C | D | E | F | H | L | M | N | Maximum size after swaging (mm) |

| 6 | 0.15 | 109 | 12.7 | 35.1 | 19.1 | 6.85 | 54 | 17.5 | 102 | 9.65 | 38.1 | 11.7 |

| 8 | 0.34 | 138 | 19.6 | 41.1 | 22.4 | 8.65 | 81 | 20.6 | 135 | 11.9 | 44.5 | 18 |

| 9~10 | 0.33 | 138 | 19.6 | 41.1 | 22.4 | 10.4 | 81 | 20.6 | 135 | 11.9 | 44.5 | 18 |

| 11~12 | 0.64 | 176 | 24.9 | 51 | 26.9 | 12.2 | 108 | 25.4 | 170 | 14.2 | 51 | 23.1 |

| 13 | 0.64 | 176 | 24.9 | 51 | 26.9 | 14 | 108 | 25.4 | 170 | 14.2 | 51 | 23.1 |

| 14 | 1.32 | 220 | 31.8 | 60.5 | 31.8 | 15.5 | 135 | 31.8 | 207 | 17.3 | 57 | 29.5 |

| 16 | 1.29 | 220 | 31.8 | 60.5 | 31.8 | 17 | 135 | 31.8 | 207 | 17.3 | 57 | 29.5 |

| 18~20 | 2.27 | 261 | 39.4 | 73 | 36.6 | 20.3 | 162 | 38.1 | 254 | 19.8 | 70 | 36.1 |

| 22 | 3.08 | 303 | 43.2 | 79 | 42.9 | 23.9 | 189 | 44.5 | 295 | 23.9 | 82.5 | 39.4 |

| 24~26 | 4.72 | 344 | 50.5 | 92 | 52.5 | 26.9 | 216 | 51 | 340 | 26.9 | 95.5 | 45.7 |

| 28 | 6.72 | 382 | 57 | 102 | 58.5 | 30.2 | 243 | 57 | 381 | 30.2 | 108 | 52 |

| 32 | 9.78 | 430 | 64.5 | 114 | 65 | 33.8 | 270 | 63.5 | 419 | 31 | 121 | 58.5 |

| 34~36 | 12.9 | 473 | 71 | 127 | 65 | 36.8 | 297 | 63.5 | 461 | 35.1 | 133 | 65 |

| 38~40 | 17.3 | 511 | 78 | 140 | 71.5 | 40.1 | 324 | 76 | 502 | 42.9 | 146 | 71.5 |

| 44 | 23.1 | 598 | 86 | 159 | 90.5 | 47.2 | 378 | 89 | 584 | 53.5 | 171 | 77.5 |

| 48~52 | 40.5 | 702 | 100 | 184 | 96.5 | 53.5 | 432 | 102 | 683 | 60 | 203 | 90.5 |

Note:

1. Data in the table is from sample test. It is only for reference purposes with no guarantee or warranty as to its accuracy. The real data may vary slightly as test methods or ambient environments such as weather, temperature, humidity, etc. change.

2. Apart from industrial standards that the swage terminal is manufactured to, Junwei also offers customized products as per your requirements. For details, please feel free to contact us.

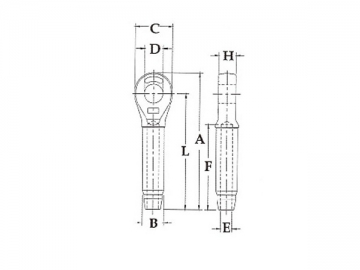

| Wire rope diameter (mm) | Weight each (kg) | Size before swaging | Maximum size after swaging (mm) | |||||||

| A | B | C | D | E | F | H | L | |||

| 6 | 0.15 | 109 | 12.7 | 35.1 | 19.1 | 6.85 | 54 | 12.7 | 89 | 11.7 |

| 8 | 0.34 | 138 | 19.6 | 41.1 | 22.4 | 8.65 | 81 | 17 | 114 | 18 |

| 9~10 | 0.33 | 138 | 19.6 | 41.1 | 22.4 | 10.4 | 81 | 17 | 114 | 18 |

| 11~12 | 0.64 | 176 | 24.9 | 51 | 26.9 | 12.2 | 108 | 21.8 | 146 | 23.1 |

| 13 | 0.64 | 176 | 24.9 | 51 | 26.9 | 14 | 108 | 21.8 | 146 | 23.1 |

| 14 | 1.32 | 220 | 31.8 | 60.5 | 31.8 | 15.5 | 135 | 27.7 | 184 | 29.5 |

| 16 | 1.29 | 220 | 31.8 | 60.5 | 31.8 | 17 | 135 | 28.7 | 184 | 29.5 |

| 18~20 | 2.27 | 261 | 39.4 | 73 | 36.6 | 20.3 | 162 | 33.3 | 219 | 36.1 |

| 22 | 3.08 | 303 | 43.2 | 79 | 42.9 | 23.9 | 189 | 38.1 | 257 | 39.4 |

| 24~26 | 4.72 | 344 | 50.5 | 92 | 52.5 | 26.9 | 216 | 44.5 | 292 | 45.7 |

| 28 | 6.72 | 382 | 57 | 102 | 58.5 | 30.2 | 243 | 51 | 324 | 52 |

| 32 | 9.78 | 430 | 64.5 | 114 | 65 | 33.8 | 270 | 57 | 365 | 58.5 |

| 34~36 | 12.9 | 473 | 71 | 127 | 65 | 36.8 | 297 | 57 | 400 | 65 |

| 38~40 | 17.3 | 511 | 78 | 140 | 71.5 | 40.1 | 324 | 63.5 | 432 | 71.5 |

| 44 | 23.1 | 298 | 86 | 159 | 90.5 | 47.2 | 378 | 76 | 508 | 77.5 |

| 48~52 | 40.5 | 702 | 100 | 184 | 96.5 | 53.5 | 432 | 82.5 | 584 | 90.5 |

Note:

1. Data in the table is from sample test. It is only for reference purposes with no guarantee or warranty as to its accuracy. The real data may vary slightly as test methods or ambient environments such as weather, temperature, humidity, etc. change.

2. In addition to industrial standards that the swage terminal is manufactured to, Junwei offers customized products as per your requirements. For details, please feel free to contact us.