PEX-AL-PEX Solar Pipe

Overlapped Welding

| Size(mm) | Palconn Code |

| 1216 | PAP-OW16 |

| 1620 | PAP-OW20 |

| 2026 | PAP-OW26 |

| 2632 | PAP-OW32 |

| Size(mm) | Palconn Code |

| 1216 | PAP-BW16 |

| 1620 | PAP-BW20 |

| 2026 | PAP-BW26 |

| 2632 | PAP-BW32 |

| Heat Conduction Coefficient | 0.45W/(m.K) |

| Expansion Coefficient | 2.5x10-5(m.k) |

| Bend Radius | >=5D |

| Working temperature | -40-+95°C |

| Working Pressure | 1.25MPA |

| Oxygen Diffusion | 0mg/1.d |

| Burst Pressure | >=4.0-7 MPA |

| Tensile Resistance | >2100-2650N |

Application of PEX-AL-PEX Solar Pipe

1. Compared to a traditional metal pipe, the composite pipe has the same strength and easy bendability.

2. Outstanding properties in regards to a high temperature, high pressure and corrosion resistance.

3. The smooth inner surface decreases the resistance to fluids. This offers the pipe a 30% more efficient ability to conduct water.

4. Outstanding heat preservation: the heat conduction coefficient is 0.45W/m.k, which is less than a traditional metal pipe, and saves on the need for insulation materials outside of the pipe.

5. Easy to cut and install

6. The service life of the composite solar pipes is more than 50 years.

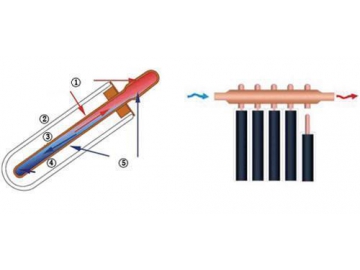

The PEX-AL-PEX solar pipe is a composite pipe of 5 layers. The inner and outer layers are made of a cross-linked (PEX) that has been tightly bonded with a melt adhesive to the middle layer aluminum core. That core is welded lengthwise in either a butt welding or overlap welding method, making this pipe an ideal choice and combination of metal and plastic.