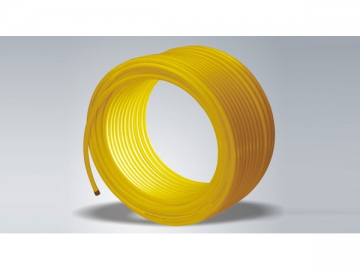

PERT Pipes and Fittings

The PERT underfloor heating pipes and their fittings are made using 4731B PE-RT materials. They reach the standards of ISO/DIS 22391:2007 and DIN 16833:2007.

Applications

The PE-RT pipes and fittings are mainly used for low temperature floor radiant heating system and hydronic heating system.

PE-RT Pipes Features

1. Superior long term hydrostatic strength;

2. Excellent impact strength;

3. Great toughness at normal and low temperature (to -40℃);

4. Smooth inner surface for small resistance to flow;

5. Heat welding ensures no leakage of the whole underfloor heating system

| Product Name | Item Number | Series | Specifications | Package (m/ coil) |

| PE-RT floor radiant heating pipe | 050005001 | S5 | 2 0 ×2.0mm | 220 |

| 050005002 | 25×2.3mm | 110 | ||

| 050005003 | 32×2.9mm | 55 | ||

| 050004001 | S4 | 20×2.3mm | 220 | |

| 050004002 | 25×2.8mm | 110 | ||

| 050004003 | 32×3.6mm | 55 | ||

| 050003001 | S3.2 | 20×2.8mm | 220 | |

| 050003002 | 25×3.5mm | 110 | ||

| 050003003 | 32×4.4mm | 55 |

Standards: ISO/DIS 22391:2007, DIN 16833:2007 Fittings:

PERT 20 PERT 25 PE-RT Pipe Coil, White Male Elbow Female Elbow Male Coupling Equal Tee 90° Elbow End Cap Coupling Stainless Steel Manifold Copper Manifold PE-RT Heat Welding Machine Die Heads for PE-RT Heat Welding Machine

Kingbull PE-RT Pipes Advantages

1. We only use the top quality PE-RT materials without addition of recycled materials.

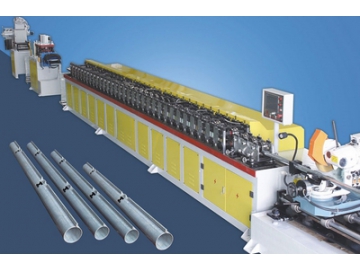

2. We run the original Battenfeld PE-RT pipe extrusion line with KIV forced feed system and advanced BM barrier screw, realizing high speed extrusion at low speed and retaining complete performance.

3. Advanced cooling and sizing system and technique account for high production speed, stable molding, high dimensional accuracy and stability and great appearance.

4. Online control maximizes size accuracy.

5. 100% air pressure test (2MPa, 2min) completely eliminate the potential risk of underfloor installation.

6. We boast complete set of cutting edge test equipment.

7. As the largest and the earliest manufacturer of PE-RT pipes in China, we can product 30t PE-RT pipes a day. Calculating by dn20*S5, we have a production capacity of about 250,000m/d.

8. We strictly enforce three-class quality control system and run standard quality management system.

9. Industry leading ERP system and perfect pipe coding information and production operating record system make production of the pipes traceable.

10. Kingbull boasts rich experience in design and construction of PE-RT floor heating pipes. We can provide you with complete set of auxiliary equipment and materials. You can enjoy one-stop service here.