Steel Wire Hot-Dip Galfan Coating Line (Galfan® coated steel wire production line)

This steel wire hot-dip Galfan coating line is also called Galfan coated steel wire production line. It is suitable for the galvanizing of various steel wires, including low carbon steel wire, medium carbon steel wire, and high carbon steel wire. You are welcome to see more details on this steel wire galvanizing equipment below.

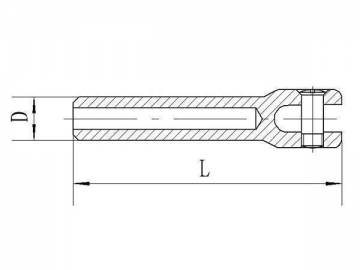

Specification of the steel wire hot-dip Galfan coating line

- Steel wire: high/medium/low carbon steel

- Diameter: 1.6~4.0mm, 4.0~8.0mm

- Plating thickness: 150~450g/m2

- Wire number: 6~24 wires

- DV value: 30~120 mm•m/min

- Production capacity: 1000~20000 ton/year

Process flows for different steel wire hot-dip Galfan coating line

Traditional single layer galvanizing technique (complex flux solution treatment)

Wire feeding (disk type/spool type) - electrolytic degreasing - water rinsing - fumeless acidic rinse - water rinsing - drying - hot-dip galvanizing (electricity/natural gas/ liquefied petroleum gas) - wiping (nitrogen/oiled charcoal) -air/water cooling - post treatment (passivation/waxing) - wire take-up (inverted type/spool type)

Latest single galvanizing technique (exclusive flux solution for Galfan coating of the steel wire hot-dip Galfan coating line)

Wire feeding (disk type/spool type) - electrolytic degreasing - water rinsing - fumeless acidic rinse - water rinsing - flux solution (exclusive flux solution for Galfan coating) - drying - hot-dip galvanizing (electricity/natural gas/ liquefied petroleum gas) - wiping (nitrogen/oiled charcoal) -air/water cooling - post treatment (passivation/waxing) - wire take-up (inverted type/spool type)

Traditional double layer galvanizing equipment

Wire feeding (disk type/spool type) - electrolytic degreasing - water rinsing - fumeless acidic rinse - water rinsing - regular flux solution treatment - drying - hot-dip galvanizing (electricity/natural gas/ liquefied petroleum gas) - wiping (nitrogen/oiled charcoal) -air/water cooling - post treatment (passivation/waxing) - wire take-up (inverted type/spool type)

Among the steel wire hot-dip Galfan coating lines specified above, we recommend the latest single galvanizing technique using exclusive flux solution for Galfan coating. The reasons are as follows.

- No extra machines are needed on the basis of traditional techniques, saving you 15-20% equipment investment.

- Our patented flux solution for Galfan coating is cheaper than that of traditional single Galfan plating and double Galfan plating, making the production cost 12-16% lower.

- The Galfan layer is plated at one time, so the coating is better adhesive, toughness, torsion resistance, and smoothness than that treated by traditional techniques.

Spool type pay-off machine

Spool type pay-off machine  Vertical spool type pay-off machine

Vertical spool type pay-off machine  Horizontal spool type pay-off machine

Horizontal spool type pay-off machine  Electrolytic degreasing bath

Electrolytic degreasing bath  Hot alkaline rinsing bath

Hot alkaline rinsing bath  Hot water rinsing bath

Hot water rinsing bath  Water rinsing bath

Water rinsing bath  Enclosed type fumeless acidic rinsing bath

Enclosed type fumeless acidic rinsing bath  Fumeless acidic rinsing bath

Fumeless acidic rinsing bath  Electric drying furnace

Electric drying furnace  Gas drying furnace

Gas drying furnace  Electric ceramic galvanizing kettle

Electric ceramic galvanizing kettle  Gas fired galvanizing kettle

Gas fired galvanizing kettle  Nitrogen wiping

Nitrogen wiping  Air/water cooling

Air/water cooling  Inverted take-up machine

Inverted take-up machine