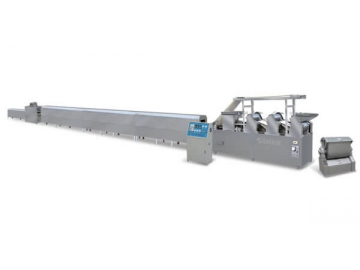

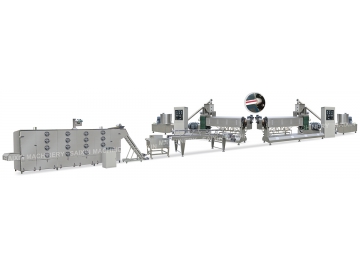

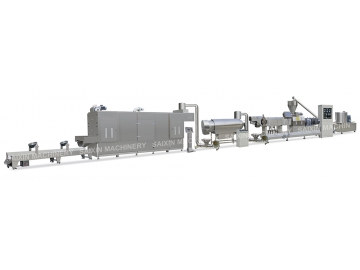

Biscuit Processing Line

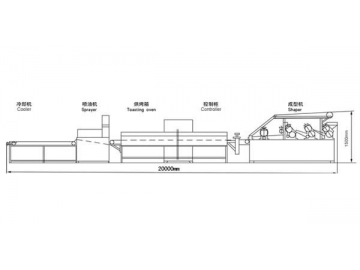

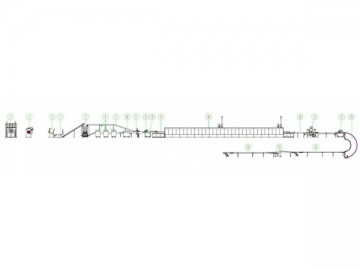

Originally designed based on acquired Japanese technology, our automatic biscuit processing line features compact structure and high automation. The entire working process of the biscuit processing line, from dough making, shaping, baking, oil spraying, and cooling, can be accomplished at one time.

Thanks to hundreds of molds and dozens of technology formulas, it is possible for the biscuit processing line to produce all kinds of popular biscuits such as soft biscuit, hard biscuit, cream core filling biscuit, vegetable biscuit, calcium biscuit, multi-vitamin biscuit, etc.

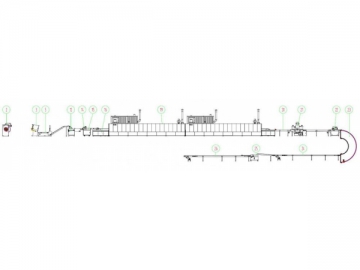

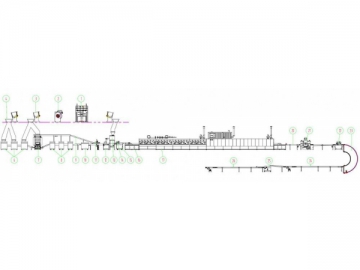

Sample Photos| Parameters/Model | DXB225 |

| Input Voltage | 380V/50Hz |

| Installed Capacity | 28.5kw |

| Die-plate Roller | φ205×205mm |

| Toasting Temperature | 200-300℃ |

| Output | 50kg/h |

| Acting Width | 200mm |

| Dimension | 18×0.6×1.5m |

| Weight | 1500kg |

| Model/Parameters | Input Voltage | Power | Output | Weight | Dimension |

| DXB225 | 380V/ 50Hz | 28.5kw | 50kg/h | 1500kg | 18×0.6×1.5m |

| DXB280 | 380V/50Hz | 56kw | 100kg/h | 2500kg | 26×0.8×1.5m |

| DXB400 | 380V/50Hz | 120kw | 200kg/h | 4000kg | 45×1.0×1.5m |

| DXB600 | 380V/50Hz | 200kw | 400kg/h | 10000kg | 70×1.2×1.75m |

| DXB1000 | 380V/50Hz | 300kw | 800kg/h | 15000kg | 100×1.85×2.45m |

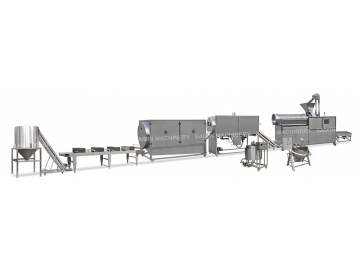

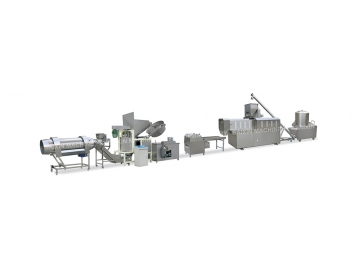

As a professional biscuit processing line manufacturer based in China, SAIXIN is engaged in the design and manufacture of not only biscuit making machine, but instant noodle processing line, macaroni processing line, etc. As a result of our rigorous quality and cost control measures, we are able to supply quality food processing machinery at competitive prices.