Vibratory Finishing Tank, Vibratory Finishing Tube

Request a Quote

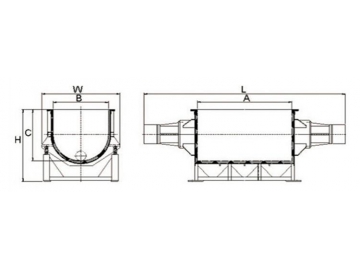

The vibratory finishing tank, an ideal machine for deburring, polishing, rust removal or other finishing, is appropriate for large and long workpieces, such as engine case, marble plate, electronic component base plate and so on. Compared to the finishing machine bowl, the finishing tank provides more powerful grinding force and higher working efficiency.

Features- The vibratory trough is equipped with several small vibration compartments to separate different workpieces and satisfy the requirements of different finishing medias.

- The electronic control system brings semi-automatization aimed at sampling workpiece at any time during finishing.

- High-wear-resistance polyurethane is used as the inner liner to alleviate the collision between the workpiece and vibration cell, reduce the noise and extend the working life.

- 2 Three-phase vibration motors with changeable amplitudes from 0.3mm-10mm are equipped with to provide uniform vibration forces.

- Size and number of the baffle inside can be customized according to your requirement.

| Model | Capacity (L) | Outer Size (mm) | Inner Length (mm) A | Inner Diameter (mm) B | Inner Height (mm) C | Motor Power (kw) | Line Thickness (mm) | |

| CL-500 | 500 | 2670×1000×985 | 1310 | 700 | 690 | 2*2.2 | 25 | |

| CL-900 | 900 | 2700×1050×1150 | 1200 | 850 | 900 | 2*4.0 | 25 | |

| CL-1200 | 1200 | 3000×1050×1100 | 2000 | 850 | 750 | 2*4.0 | 25 | |

| CL-1800 | 1800 | 3500×1336×1256 | 2000 | 940 | 1120 | 2*5.5 | 25 | |

| CL-2800 | 2800 | 3300×1830×1740 | 1580 | 1270 | 1500 | 2*9.0 | 25 |

Related products

Send Message

Most Recent

More

Other Products

Videos