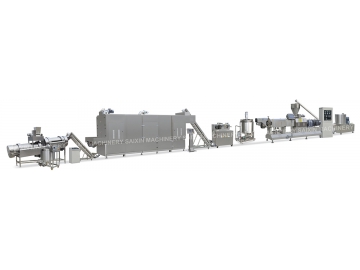

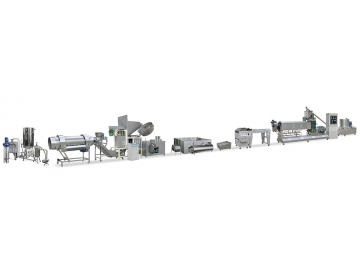

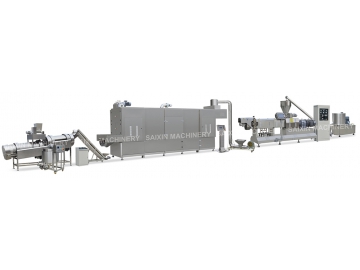

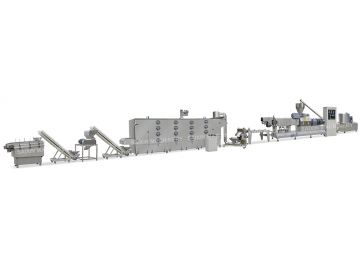

Extruded Baked Snacks, Direct Expanded Snacks Processing Line

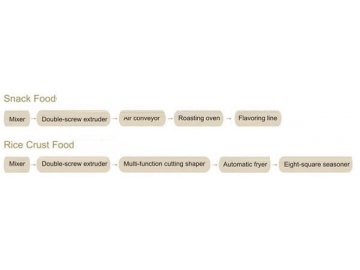

The reason why baked snacks are the most popular in today's snack market is because people prefer to have healthy food with less oil or no oil. Our extruded baked snacks processing line also offers cream core filling snacks and chocolate core filling snacks to customers. By changing different shapes of extruder dies, we can offer customers many different shapes of snacks products including star, ring, ball, pillow, numbers, heart, curl, wheel, tube, stick, etc.

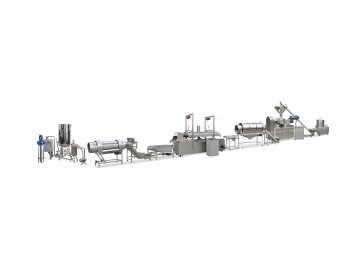

The extruded baked snacks processing line, also called the direct expanded snacks processing line, puff snacks processing line is our most popular line of our puff snacks making machines. Consisting of a feeding system, extrusion system, cutting system, heating system, transporting system, and cooling system, our direct expanded snacks processing line is designed with advanced screw extrusion technology. Our extruded baked snacks processing line utilizes low temperature to make materials ripe and shaping at one time. The complete set of automatic control system and frequency and speed control system offers stability to the process.

Our extruded baked snacks processing line is a fully automatic line. The line process procedure includes raw material mixing, extrusion, core filling, cutting, drying and oil spraying, and seasonings powder spraying. The direct expanded snacks processing line can process different types of food materials The raw materials for this line can be corn flour, rice flour, wheat flour, soybean powder, or oat flour. Almost all grain materials can be used on this line. This extruded baked snacks processing line is designed and manufactured from advanced Italian extrusion technology, offering customers direct expanded snack food without frying procedure.

Sample Photos 1.Raw material mixer

2.Screw conveyor

3.Twin screw extruder

4.Core filling machine

5.Multifunction shaper

6.Belt elevator

7.Air conveyor

8.Multi-layer oven

9.Double roller flavoring line

| Parameters/Model | DS56-III Twin Screw Extruder Processing Line |

| Input Voltage | 380V/50Hz |

| Installed Capacity | 69kw |

| Power Consumption | 45kw |

| Output | 120-150kg/h |

| Length | 26m |

To guarantee food security, we commit ourselves to producing high quality food processing equipment. For this purpose we introduce advanced technology to improve the product quality and employ experienced administrative staff and technicians. We strengthen the quality control by establishing related standards. In addition, the standard management enables us to provide high quality twin screw extruder and extruded baked snacks processing line to you at a competitive price. We look forward to working with you!