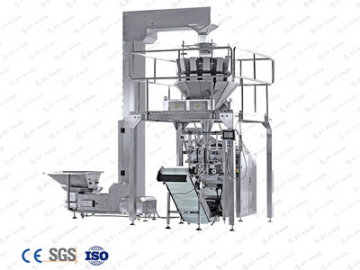

Sachet Filling Sealing Machine (100g-1000g)

The complete packaging system uses roll stock film to automatically produce both pillow type or side-gusseted bags. This sachet filling and sealing is ideally used for packaging seasonings, flour, spices, chemicals, detergents and more.

The automatic sachet filling sealing machine is designed for ground coffee, flour, spices, salt or instant drink mixes. Pouch protects products like baby-food powder, tea powder, milk or protein powder from moisture and helps them to maintain their properties. It is also widely used for non-food powders like enzymes, detergent powder or chemical additives. However, powder packing solutions may vary, depending on the type of powder, its bulk density and flowability.

This automatic sachet filling sealing machine for powder and granular products is a great solution for your powder packaging. As a vertical form fill and seal bagger, it's an effective and compact complete packaging system.

- Siemens/Omron PLC &5.7″ Omron colorful touch screen controller

- Single/dual Panasonic servo-driven motor for film infeed and conveying

- Film auto tracking, length registered by Omron photoelectric sensor & encoder

- With date coder for printing batch number, production & expiry date

- Simple and fast bag size change-over with one-piece forming sets

- Heavy-duty jaw assembly houses a cushion for shock and noise abatement

- Adjustable dwell time for better looking seals and increased packaging speeds

- Unique pneumatic film-reel locking structure to avoid film deflecting

- Independent temperature adjustment

- Various types of heating sealable laminated films namely PE/BOPP, CPP/BOPP, CPP/PET, PE/NYLON, PP/PE, PE/PET, PAPER/PE, aluminum foil based can be run on the machine. (Monolayer Polyethylene Film Sealing Jaw configuration is optional.)

| Model | |||||

| Bag type | Pillow type bag: gusseted bag / flat bottom bag (option) | ||||

| Operation mode | Intermittent | ||||

| Speed | Up to 80 bags/min | 20 to 70bags/min | |||

| Bag length(single stroke) | 20 to 280mm(0.8″ to11″) | 50 to 340mm(2.0″ to13.4″) | 50to460mm(1.9″ to 18″) | ||

| Bag width | 40 to 200mm(1.6″ to 7.9″) | 80 to 260mm(3.1″ to 10.3″) | 80 to 350mm(3.1″ to13.8″) | ||

| Packing weight | 10g to 1000g | 200g to 2000g | 500g to 3500g | ||

| Reel film width | ≤420mm(16.5″) | 540mm(21.2″) | ≤730mm(28.7″) | ||

| Reel outer dia. | 400mm(15.7″) | 400mm(15.7″) | 500mm(19.7″) | ||

| Reel inner dia. | 75mm(2.9″) | ||||

| Film thickness | 0.04-012mm(40-120mic.) | ||||

| Power supply | AC, 220V/50Hz,1-phase or as per product specification | ||||

| Power consumption | 3kW | ||||

| Compressed air requirement | 0.6 MPa, 0.36m3/min | ||||

| Machine weight | 600kg | 800kg | 1000kg | ||