AWS E309-16

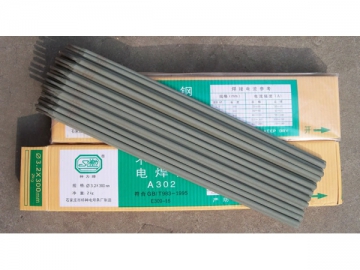

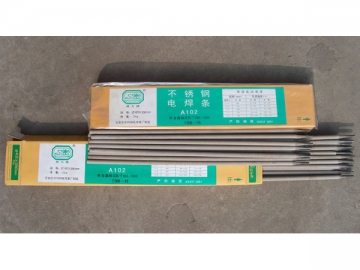

Stainless Steel Welding Rod / Welding Wire / Welding Electrode

Introduction:

The E309-16 is a Cr23Ni13 stainless steel electrode with a lime-titania coating. The deposited material is crack resistant and features outstanding oxidation resistance thanks to additional materials added. All other ingredients are equivalent to international standards.

Applications:

Used for welding stainless steel, stainless steel lining, Cr19Ni9 ( same as low-carbon steel), high-chrome steel, high-manganese steel, etc.

Chemical Composition of Deposited Metal (%):

| Chemical Composition | C | Mn | Si | S | P | Cu | Ni | Mo | Cr |

| Guarantee Value | ≤0.15 | 0.5~2.5 | ≤0.90 | ≤0.030 | ≤0.040 | ≤0.75 | 12.0~14.0 | ≤0.75 | 22.0~25.0 |

Mechanical Properties of Deposited Metal:

| Test Item | R m (MPa) | A(%) |

| Guarantee Value | ≥550 | ≥25 |

Reference Current (DC ):

| Electrode Diameter(mm) | φ2.0 | φ2.5 | φ3.2 | φ4.0 | φ5.0 |

| Welding Current (A) | 40~80 | 50~100 | 70~130 | 100~160 | 140~200 |

Packing Details:

In carton of 20kgs/net, consisting of 8 boxes x 2.5kgs for 2.5mm, & 4 boxes x 5kgs for other sizes.

With/ without pallets (fumigation-free pallets) upon customer’s request.

Instructions:

1. The electrodes should be baked under 200-250℃ for an hour before welding.

2. D/C is preferred and the current should not be too strong.