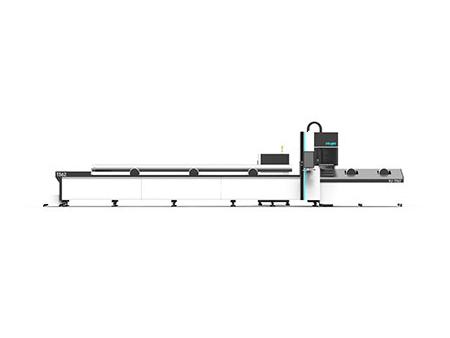

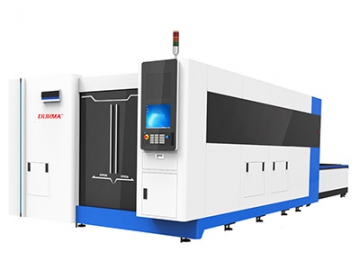

Fiber Laser Tube Cutting Machine

Request a Quote

Description

The PL series fiber laser tube cutting machine is specially developed and designed by our company aiming at tube profile cutting operations. This series of fiber laser tube cutting machines are highly cost effective, complying with the needs of sheet metal processing industry.

| Description | Specification | |

| Chuck clamping range | ∮20-∮150 | |

| Accuracy | X,Y-axis positioning accuracy | 0.02mm/m |

| X,Y-axis repeatability accuracy | ±0.03mm | |

| Speed | X/Y-axis max. speed | 80 m/min |

| X,Y-axis max. acceleration speed | 60 m/min | |

| W axis max. rotation speed | 30rpm/min | |

| Power | Phase | 3 |

| Rated voltage | 380V | |

| Frequency | 50Hz | |

| Rated power of laser generator | 2000W | |

| Number of chuck | 2 | |

| Chuck control type | Automatic clamping | |

| Cutting thickness (within cutting range) | Carbon steel 12mm | |

| Stainless steel 6mm | ||

| Machine outline dimension size | 11m×3m×2m | |

| Total weight | 5000kg | |

- FSCUT3000 numerical control system

- YLR-1500 laser generator (IPG)

- Cutting head (Switzerland Raytools)

- Water cooler

- Assisted gas proportional control system (Japan SMC)

- High-pressure tube cutting system

- Fan for exhausting smoke and dust removal

- The main machine frame is a sturdy steel-plate welded box structure and through furnance for high-temperature tempering to thoroughly eliminate welding stress, allowing for good stability during laser cutting process.

- The fiber laser cutting machine is standardly configured with assisted low-pressure oxygen cutting system, mainly used for cutting carbon steel tubes. When the users need to cut stainless steel, the high-pressure cutting system can be utilized to control high-pressure assisted cutting gas, nitrogen.

- PL type fiber laser tube cutting machine can be equipped with Switzerland RayTools fiber laser cutting head with convenient and fast focal length setting. The specific features are as follows.

(1). The protective lens is configured under the focusing mirror. With slide installation method, it is convenient and fast for replacement. Besides, the sealing property is good, effectively prolonging the service life of the focusing mirror.

(2). Inside the cutting head are integrated with cooling water, assisted gas, cooling air and sensor signal lines, which can effectively reduce damage to those parts during laser cutting process. - The laser cutting machine is equipped with multi lifting support systems that can realize manual lifting as well as numerical controlled auto lifting.

Related products

Send Message

Most Recent

More

Other Products

Videos