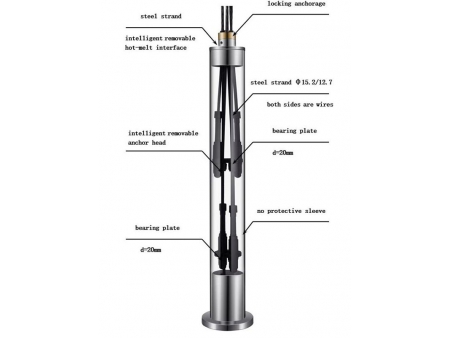

Type RXI Temporary Strand Anchor

Type RXI temporary strand anchor has integration functions of recoverable, real-time monitoring of internal force and prestress stress dispersive. It is applicable in foundation pit which is deep. Its advantages include high work efficiency, real-time monitoring of internal stress, removable after construction completed.

① Force measurement component included

② Data transmission by the wire

① Steel strand

② Wire

- Slope

- Temporary slope

- Counteracting uplift forces structure

- Fixation of bridge bearing platform

- Construction process: Jet grouting

- Diameter of bearing plate: 205mm

- Thickness of bearing plate: 20mm

- Function type: hot melt removable, real-time monitoring of internal force

- Environmental friendly level: Environmental friendly PE, do not pollute the underground water

- Suitable steel strand type:Φ15.2/Φ12.7

- Suitable grouting pipe: not required

- Intelligent real-time monitoring of internal force

The strain gauge located at the fixed end of the freely-deforming tendon boy which located at the head of the anchoring section of the end. The strain gauge is wrapped in filler. The accuracy of the conventional strain gauge can only monitor each anchor whereas the intelligent anchor can monitor up to the internal force of each steel strand in the anchor. It has higher accuracy and allows the analysis of the distribution of the bearing capacity of each unit anchor based on the measurement. - Hot melt recoverable function

Hot melt recoverable ground anchor implements the hot melt removable technology and automatic recovery equipment to help removing all the tendon bodies upon the completion of the bracing work. This enables material saving and protecting the soil in the meantime providing a green construction environment for the adjacent underground space, effectively solving the problem of leftover tendon residue in the soil. - Compressive stress dispersive

Form an underreamed anchoring section at the bottom plate of the anchor using the jet grouting process and distributes the bearing plate over the anchoring section reasonably. Hence, the dispersion of the internal stress can be achieved.

Q1: What is jet grouting?

A: The jet grouting process mainly adopts an improvised high-pressure rotary spray method to form an anchoring section of the rotary spray underreamed anchor on the bottom plate of the anchor.

① Unbonded tendon with wire;

② Free segment;

③ Hot melt anchor;

④ Bearing plate;

⑤ Anchoring section;

⑥ Anchor;

⑦ Base plate

Q2: Is the intelligent force measurement of this product measuring each anchor?

A: The accuracy of the intelligent anchor measurement measures up to each steel strand.

Q3: How is the measured data observed?

A: Real-time observation can be made via mobile gadgets, computer and so on as the data is transmitted to the device via wireless transmission after on-site measuring.

Q4: What is the size of the casing used by this product?

A: This product adopts jet grouting process in construction instead of casing. For ground layer that is hard and direct advancement is not allowed, three-wings drilling bit is used to drill holes beforehand followed by jet grouting.

Q5: How is the safety level of this product?

A: The static load coefficient of the hot melt removable anchor reached 96% which is nearly the same as the strength of steel strand. Besides, it satisfies the large fatigue test up to 2 million times and therefore it is applicable in permanent structure.

Q6: How is the recovering speed?

A: With the use of fully automatic recovering equipment, taking 6 anchors with length 25 meters as an example, a group of 2 people in assembly line can complete the recovery of 90 anchors.

Q7: How much is the recovery rate of the anchor?

A: The rate is higher than 95% normally. Approaches can be made to realize 100% recovering rate.

Q8: How many cable structures can this product built up at most?

A: Using only this model, 6 cables can be built at most where the largest internal diameter of the anchor rod body is 205mm.