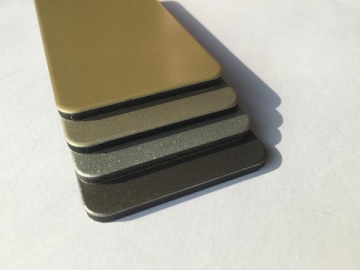

PVDF Coating Aluminum Composite Panel

Application

Since PVDF coating is retardant to external environment's damage, it could be used for more than twenty years in general, so PDVF coating aluminum composite panel is always applied in buildings' exterior walls. When choosing Aluwedo's PDVF coating aluminum composite panel, not only decreased cost, finest quality could also be guaranteed.

Features

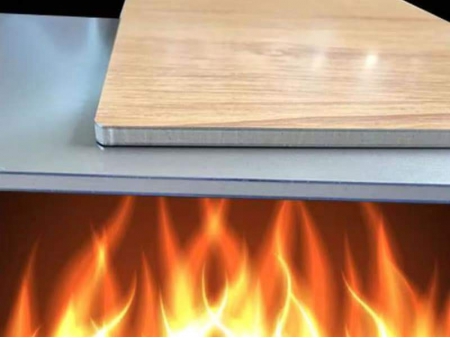

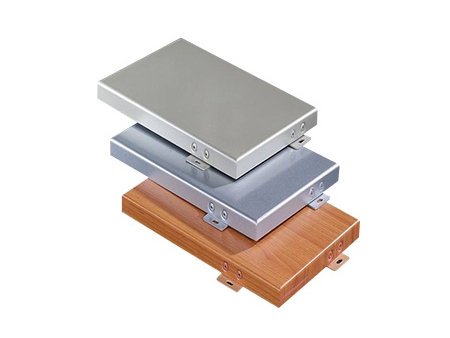

PDVF coating aluminum composite panel gets rid of the disadvantages of traditional ACP and possesses many extra outstanding properties, like, gorgeousness, decorativeness, weather resistance, corrosion resistance, impact resistance, humidity resistance, thermal resistance, vibration resistance, fire-proof and sound-proof, light weight, workability, and easy to install and transport, while not sacrificing the original strength of its raw materials – aluminum and PE materials.

| Specifications Of Aluminum Composite Panel | |

| Normal Width | 1220mm, 1250mm, 1500mm, 1570mm, 2000mm |

| Panel Thickness | 2mm 3mm 4mm 5mm 6mm |

| Aluminum Alloy | AA1100,AA3003,AA5005(Other Grade On Requirements) |

| Aluminum Skin Thickness | 0.08mm ~ 0.60mm |

| Coating | PE/PVDF/FEVE/NANO/Anti-scratch/Mill |

| PE Core | Recycle PE Core/Fireproof PE Core/Unbreakable PE Core |

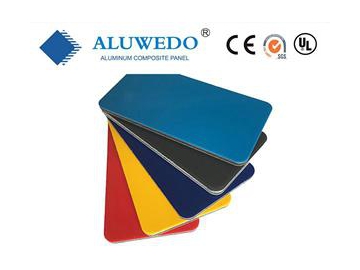

| Color | Solid/ Glossy/Matt/Metallic/Marble/Wooden/Brush/Mirror/Embossed |

| Length | 5800mm in maximum for 20ft container |

| Delivery | 15 to 20 days after order confirmed and receiving deposit |

| MOQ | 600 to 1000 m2 per color |

| Brand/OEM | ALUWEDO®/ Customized |

| Payment Terms | T/T/ L/C at sight/Western Union |

| Packing | By bulk; In Wooden Package |

| Testing Item | Standard | Result |

| Unit Weight | ASTM D792 | T 4mm=5.5kg/m2 |

| Thermal Expansion | ASTM D696 | 24-28 |

| Thermal Deformation Temperature | ASTM D648 | 115 ℃ |

| Thermal Conduction | ASTM D976 | 0.102kcal/m.hr ℃ |

| Flexural Rigidity | ASTM D393 | 14.0*10^5 |

| Impact Resistance | ASTM D732 | 1.64kgf |

| Adhesive Strength | ASTM D903 | 0.77kg/mm |

| Flexural Elasticity | ASTM D790 | 4030kg/mm2 |

| Shear Resistance | ASTM D732 | 2.7kgf/mm2 |

| Fire Propagation | ASTM E84 | Qualified |

| Wind-Pressure Resistant | ASTM E330 | Passed |

| Properties Against Water | ASTM E331 | Passed |

Description

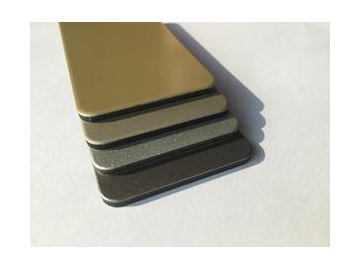

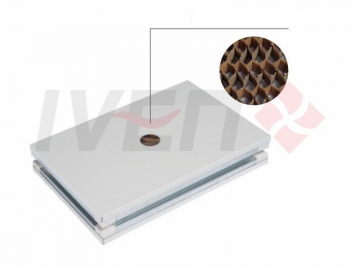

PDVF coating aluminum composite panel enjoy an integral structure of two rust-proof aluminum panels, LDPE (low density polyethylene) and DUPONT's polyolefin membrane. They are laminated together at high-temperature and high-pressure condition. Meanwhile, since 70% PDVF coating is introduced to its surface, excellent weather resistance and scald resistance could be addressed to our aluminum composite panels. Besides, a corrosion-resistant coating is also carried out on our aluminum panel's bottom.

Aluwedo is a reliable PVDF coating aluminum composite panel manufacturer and supplier, offers a wide range of interior and exterior decorative ACP panels for customers. Our aluminum composite panels can be used as architectural wall cladding, building façade, advertising signage, commercial entryway, etc. From the raw material selection, panel manufacturing and surface coating, each step is under strict control, we are sure to offer quality PVDF coated ACP composite panels with competitive prices.