HDPE Same Floor Drainage System

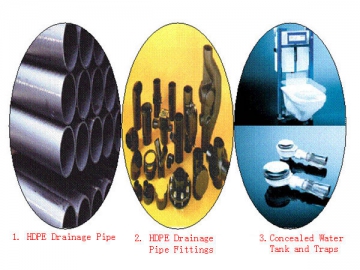

The HDPE same floor drainage system installed on the same floor of a building mainly consists of three parts:

1) HDPE pipes and fittings;

2) Concealed water tank, horizontal floor drain, and other special accessories;

3) Wall mounted sanitary ware

Customers can choose the brand and size of wall mounted sanitary ware at will according to their preference. Other parts are supplied by Kingbull.

1. HDPE Drainage Pipe, 2. HDPE Drainage Pipe Fittings, 3. Concealed Water Tank and Traps

Especially Suitable for the Bathroom of a House

As a stylish drainage solution, same floor drainage system can be used in bathrooms for multi-storey buildings, high-rise buildings, and villas. In particular, it is ideal for the bathroom under which bedroom, living room or kitchen is located.

All concealed water tanks for the bathroom solution are imported from German. Kingbull has established close partnership with SANIT EISENBERG.

- Mechanical Type Concealed Water Tank

- Concealed Water Tank Controlled by Wire

We use quality designed concealed water tank and support which offer lots of advantages:

1) Long service life, great sealing performance without leakage;

2) High strength, no scaling;

3) Modular design, ensuring ease of assembly, disassembly and maintenance;

4) High location of water tank, excellent flushing effect;

5) With high mechanical strength, the support can bears a weight of up to 400kg, controlling the deformation within 3mm;

6) Automobile primer coating process and surface powder coating treatment for the support enable a long time of resistance to corrosion.

1.2 Inlet and Outlet Valves Features

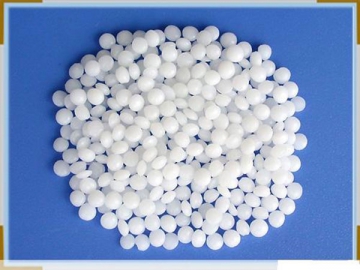

1) They use Silicone sealing rings which are highly durable and ageing resistant. Manufactured in Switzerland using water proof silicone that is usually used for high end watches, they guarantee a high longevity of 50 years and pass the 700000 times fatigue test.

2) The inlet valve comes with a slow closing function that can prevent siphoning, reduce noise and extend service life.

3) Valve body is fabricated from POM, avoiding scaling.

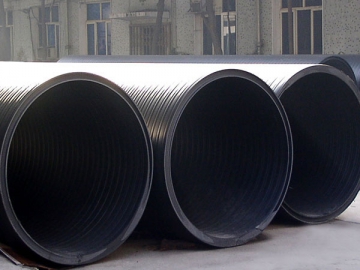

Same floor drainage system and siphonic roof drainage system share the same HDPE pipe system. The difference is that the latter system requires pipes with more specifications and larger diameters. On the contrary, the former one needs pipes in less specifications and smaller diameters. Generally, the common HDPE pipes for the same floor drainage system are available in dn50, dn75, dn110 and dn160 specifications which are the same to conventional drainage system.

Special Performances of HDPE Pipes:

Strong toughness, great impact strength;

Wear and corrosion resistance, long service life;

Heat and cold resistant;

Diverse connection methods with high safety and reliability;

Light weight, easy for handling and installation

Our high density polyethylene pipes are manufactured in complete accordance with the standards of CJ/T250-2007. And, some physical and chemical indexes such as elongation at break far exceed the standards.

Our same floor drainage system realizes efficient drainage depending on a complete set of products including many special fittings such as Sovent, multi-way spherical fitting, trap, floor drain, expansion socket, reducer, etc.

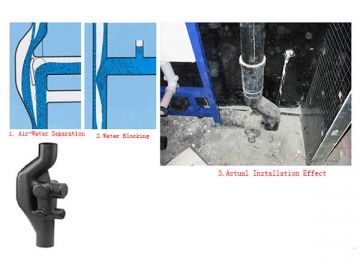

3.1 Sovent

1. Air-Water Separation

2. Water Blocking

3. Actual Installation Effect

First choice for single stack drainage system;

Realize air water separation, balance the air pressure and water pressure in pipe;

With inlets in multi specifications and directions, it allows connections for horizontal branch pipes from different directions and heights on the same floor;

Large drainage capacity, up to 7.5L/S (Note: common drain pipe: 4L/S, spiral pipe: 6L/S, double riser: 8.8L/S) Installation Method:

- 1. Clamped on thin-wall welding machine

- 2. Sawing off for branch drainage

- 3. Connect to a branch pipe

- 4. Complete

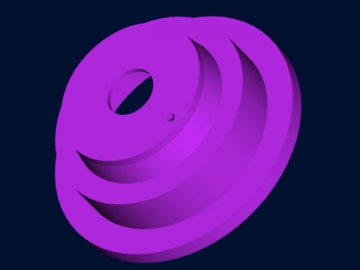

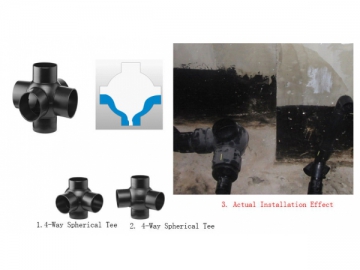

1. 4-Way Spherical Tee

2. 4-Way Spherical Tee

3. Actual Installation Effect

First, the spherical fittings are used as multi-way connectors. In addition, the capacity enlarging design at where flows come together makes for an improvement of drainage capacity. At Kingbull, we offer up to 16 spherical fitting solutions to meet the requirements of different buildings.

Main Features:

Simultaneous drainage to various directions, without interference;

Available in different opening directions, fit for connections at different directions;

Capable of enlarging the drainage capacity of the main stack;

Reduce noise

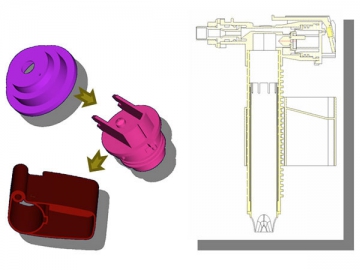

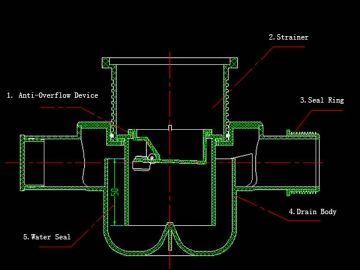

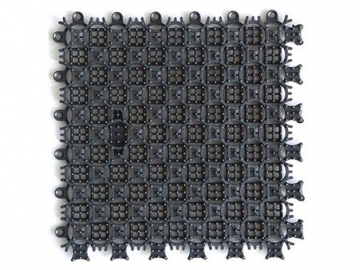

3.3. Floor Drain

In the same floor drainage system, floor drain represents the part that is the hardest to process and most likely to cause problems in the whole bathroom drainage system.

Kingbull’s self-developed two-way horizontal floor drain is made in strict line with the standard of CJ/T186:2003. It shows remarkable advantages:

1) Horizontal drain design: Effectively reduce the height of cushion;

2) Large cavity: Offer a capacity of more than 1.0 L/S;

3) Up to 50mm water seal: Put an end to return of odor;

4) With cover: Prevent water evaporation, and insects;

5) Two-way design: Simplifying pipe line;

6) High strength perforated strainer: Bear a load of 25kg without deformation

1. Anti-Overflow Device

2. Strainer

3. Seal Ring

4. Drain Body

5. Water Seal

3.4. Traps

We offer various traps to meet the demands of all drainage systems.

- P-Trap

- S-Trap

Water traps come in various types, including P-trap, S-trap and U-trap. Commonly used types are P-trap and S-trap. P-trap comes with a horizontal outlet and the outlet of S-trap is downward.

Technically, same floor drainage system unnecessarily needs connection of other traps. The traps are together with sanitary ware. Wall-hung toilet and horizontal floor drain come with traps.

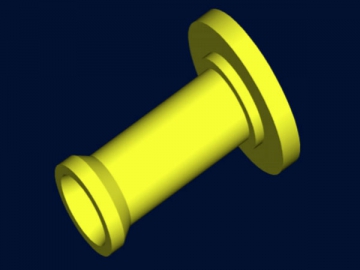

3.5. Expansion Socket, Ring Seal Socket

1) Expansion sockets are used to compensate the axial deformation of pipe caused by being heated.

a. When the storey height is 4m or less, it should be used as a fixed support for the pipe through floors; when the storey height is more than 4m, expansion amounts of the joints can be determined according to the system design.

b. On each fitting such as spherical tee, 88.5° tee and Sovent etc, an expansion socket should be fitted. It has to be listed in the statistical table of materials.

2) Reducer is used to connect HDPE pipe to the PVC-U stack, and to the drainage pipe of sanitary equipment in the bathroom, with bell mouth to the inflow of water.

Different between Expansion socket and Ring Seal Socket

Expansion socket can be used compensate the deformation of pipe and join different pipes while the reducer is only used to join different pipes. And the reducer can not be used on horizontal pipes.

- Expansion socket

- Expansion socket

- Ring Seal Socket

- 45° Tee

- 88.5° (91.5°) Swept Junction

- 88.5° (91.5°) Tee

45° tee is used at the connection of branch pipe and stack pipe. It comes with superior drainage capacity over 88.5° (91.5°) swept junction and tee. The 88.5° (91.5°) swept junction has higher drainage capacity than the 88.5° (91.5°) tee.

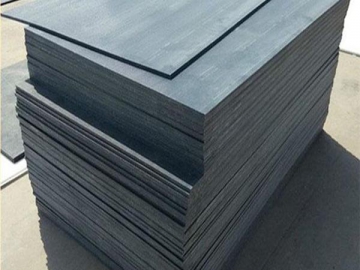

Features of HDPE Fittings for Same Floor Drainage System

The pipe fittings used in our same floor drainage system are divided into three types: outsourced injection molded fittings, purchased injection molded fittings and welded fittings. Among them, elbow and tee of less than dn200 are injection molded, with short production and purchasing cycle. Spherical tee, H pipe, expansion socket, check hole as well as dn200, dn250, dn315 elbow and tee are welded parts with long production cycle.

45° Tee, Superior in Drainage over Swept Junction

As seen from the table, 45° tee presents obviously superior drainage capacity over swept junction. The former is 1.7 times as high as the latter.

| Single stack system | Max. design drainage capacity (L/s) | ||||||

| Soil stack diameter (mm) | |||||||

| 50 | 75 | 100 (110) | 125 | 150 (160) | |||

| Vent | Stack and horizontal branch pipes | 90 ° swept junction | 0.8 | 1.3 | 3.2 | 4.0 | 5.7 |

| 45° tee | 1.0 | 1.7 | 4.0 | 5.2 | 7.4 | ||