Concrete Test Hammer

TBT-TH01 concrete test hammer is intended for carrying out non-destructive tests on concrete structures. It gives an immediate indication of the compressive strength of the concrete using the calibration curve applied each hammer.

| Measuring range | 10~60Mpa |

| Standard impact energy | 2.207Nm |

| Stroke of rebound hammer | 75mm |

| Friction of pointer slider | 0.5N~0.8N |

| Sphere radius of rebound pole (SR) | 25mm±1mm |

| Average rebound value on steel anvil (Rm) | 80±2 |

| Dimension | Φ54x278mm |

TBT-TH02Q Digital Concrete Hammer is a high-tech product, especially designed for the needs of in place test for concrete compressive strength, applied to non-destructive test (NDT) hardened concrete compressive strength component in construct projects.

| Measuring range: | 10-70MPa |

| Impact energy: | 2.207±0.1Nm (0.225Kgf.m) |

| Length of spring stretch: | 75±0.3mm |

| Tension spring stiffness: | 785±30N/m |

| Static friction of pointer slider: | 0.65±0.15N |

| Radius of spherical tip: | 25±1mm |

| Average rebound value on steel anvil (Rm): | 80±2 |

| Data storage capacity: | 200 standard components |

| Power: | 1×5# Ni-MH rechargeable battery |

| Housing dimension: | Φ54x280mm |

| Weight: | about 1kg |

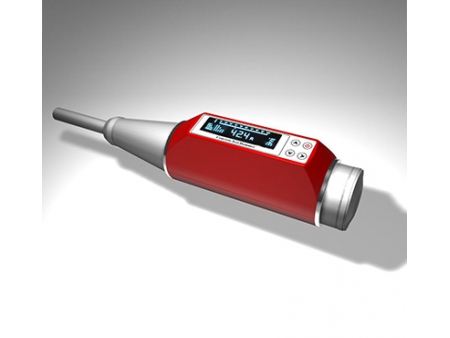

TBT-HT05D concrete hammer is an integrated digital concrete test hammer which combines data processor and test hammer into one unit. It is widely used for non destructive testing quality of concrete and building materials in finished structure or prefabricated blocks. From its rebound value, the compressive strength of con¬crete can be calculated out automatically. All testing data can be stored in memory and transferred to PC by USB cable or wireless by Blue tooth.

| Display | OLED digital |

| Measuring range | 10-100N/mm2 |

| Accuracy | ±0.1R |

| Impact energy | 0.225kgf.m (2.207Nm) for testing ordinary building and bridge construction |

| Communication | USB2.0 or Bluetooth (optional) |

| Storage | 1000 parts, 256 data for each part |

| Operating temperature | -40ºC~60ºC |

| Power supply | 3.7V Li-ion rechargeable battery charged via USB port |

| Dimension | 280x75x60mm |

| Net weight | 1.1kg |

TBT-TH05DS concrete test hammer achieves digital reporting and data sharing via USB interface and Bluetooth. This test hammer is available in wirelessly connecting to a Bluetooth printer and directly printing out test results.

Digital part can be separated from main body and coupled with mechanical hammer by a simple push. Once the hammer broke during testing, can easily exchange another hammer and continue to work. The hammer can work as normal without digital part as well. By Bluetooth data in memory can be downloaded to PC or micro printer wireless.

| Model | TBT-TH05DS |

| Type | Digital mechanical |

| Display | OLED |

| Accuracy | ±0.1 |

| Communication | USB, Bluetooth |

| Voice | NO. |

| Memory | 1000 |

| Measuring range | 10-100N/mm² |

| Impact energy | 2.207Nm |

| Spring rigidity | 785 |

| Stroke distance | 75 |

| Rebound value | 80 |

| Repeatability | Less than ±1 |

| Battery | Li-battery |

| Weight | Around 1.1kg |

| Optional printer | Yes |

- LCD large screen, high-resolution 160x160 (market product: 160x128)

- Low-power 2, 5# battery (market product: 6, 5# battery)

| Measuring range | 10~60Mpa |

| Impact energy | 2.207Nm |

| Stroke distance of strike hammer | 75mm |

| Consistency of the sample showing value | ≤±1 (digital output sampling value difference with the pointer readings) |

| Compressive strength range | 10~70N/mm2 |

| Rebound value on steel anvil (Rm) | 80±2 |

| Power | 1.5V AA alkaline battery |

| Power consumption approx. | Sampling case≤50mA (average current) |

| Storage | 80000 testing results |

Model: TBT-THP01

The instrument is medium-sized hammer used to detect the compressive strength of concrete within the range of 10-60Mpa, the standard energy is 2.207J, the indicating is a direct-reading pointer system .

Features

This hammer adopts a shell of special treatment, high hardness, long-term use without scratches, there are improvements on the processing of raw materials, precision design and service life, etc.

| Pointer length | 20.0±0.2mm |

| Pointer friction | 0.65±0.15N |

| Spherical rod end radius | 25±1.0mm |

| Stiffness of impact spring | 785±40N/m |

| Strike hammer decoupling position | the scale line "100" engraved line |

| Working lengtt for striking spring | 61.5.0±0.3mm |

| Length of impact hammer | 75±0.3mm |

| Hammer bounce position | scale "0" department |

| Rebound value on steel anvil | 80±2 (factory product control: 80-81) |

Packing list:

A box composed of a hammer, aluminum suitcase, grinding stone, bomb hit pull spring, buffer spring, screwdriver, brochures, etc.

| Length of pointer | 20.0±0.2(mm) |

| Friction of pointer | 0.65±0.15(N) |

| Sphere semi-diameter at the end of the flip rod | 25±1.0(mm) |

| Rigidity of flip tensioned spring | 785.0±40.0(N/m) |

| Location of flip hammer’s hook release | 100 at the scale mark |

| Work length of flip tensioned spring | 61.5.0±0.3(mm) |

| Strike length of flip hammer | 75±0.3 |

| Hop location of the flip hammer | “0” at the graduated scale |

| Fixed value of steel anvil | 80±2 (our products are controlled between 80-81) |

- Test anvil is an excellent instrument for assessing test hammer.

- Test anvil is made from high quality steel and special tool steel. The contact area between anvil core and anvil body has been well polished, and the rigidity of anvil core is HRC58~62.

- Test anvil must be located on horizontal ground for taking test hammer operation on it and checking the rebound value. The qualified concrete test hammer will get an average rebound value of 80±2 on test anvil, when the qualified mortar test hammer will get a rebound value of 74±2.

- The test anvil, as a calibration instrument, after each 5000 or 8000 test, the test surface can be polished for long-lasting use. The rigidity of core must be HRC58~62, or we will abolish it.

- Test anvil is usually stored in dry dustproof place that protects its rebound surface from collision.