Manufacture Capacity

LittleDuck has an excellent capacity in manufacturing wheel production tooling. We currently employ more than 50 professional technicians, and are well-versed in both domestic and international die material standards, such as the Chinese GB, American AISI, German SIN, Japanese JIS and others. In addition, we have a qualified purchasing system that is ISO 9001 certified, which ensure that the raw materials can meet design and manufacturing requirements.

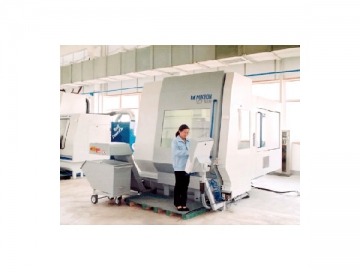

We have a diverse range of advanced production equipment for wheel spoke tooling wheel rim tooling and stamping tool manufacturing, including a large scale gantry machining center, horizontal machining center, vacuum quenching furnace, 1600T stamping line and other equipment.

We are also equipped with a range of precise testing equipment, including gantry CMM and ultrasonic NDT equipment. We also use an MRP system, standardized operating types, and lean production management patterns. This effectively guarantees the product manufacturing cycle and quality. Because of that, we can meet the needs for mass production of auto part tooling. Please feel dree to contact us if you are interested.

Main Processing Equipment- Large Scale Gantry Machining Center

Range of axis X, Y,Z: 5200×2600×920mm

Spindle speed: G6000rpm - Horizontal Machining Center

Machining range:2000×1450×1600mm

W axis range:650mm - Vertical Machining Center

Machining range: 1625×812×762mm - High-speed Machining Center

Machining range: 1000×750×750mm - Graphite Machine

Machining range: 810×410×510mm - Slow Feeding Wire-cut Machine

Machining range: 1200×700×400mm - Electric Spark Forming Machine

Machining range: 1000×600×450mm - NC lathe

Work range: 2500×800mm - Vacuum Quenching Furnace

Work range: 1000×600×420mm - Universal Tool and Cutter Grinding Machine

- Precision Die Spotting Machine

Sliding Area: 3000×2000mm

Max. Opening Daylight: 2100mm - Large Stamping Production Line

- Gantry CMM

- Ultrasonic tester