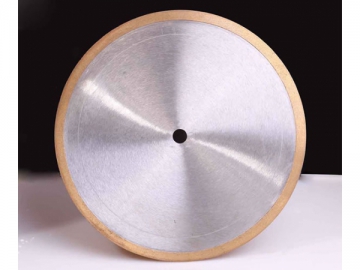

Diamond Hole Saw

The diamond hole saw is also known as the diamond core bit. It is made by electroplating high-grade synthetic diamond onto the annualr kerf of the bit, and is typically used to create a hole in the glass or marble without breaking the core. The core refers to the material that is left inside the cup-like bit after drilling.

The depth to which the diamond hole saw can cut ranges from 1.5 mm to 150mm. This diamond bit is a great choice for drilling in glass, stones and concrete.

Diamond Hole Saw User Guide

The glass hole cutter is most often installed on an ordinary electric hand drill, giving it anywhere from 800 to 1,000 rpm. Please not that this type of hole saw does not have a pilot drill bit at its center, so extreme caution should be used while operating this tool.

1. Run the core drill bit at a slow speed. Contact the glass at a 45 degree angle to open a curved slot in the glass.

2. Set the drill bit straight to the glass surface. Use the curved slot as a guide to ensure the hole is drilled in the precise location.

3. Don't run the drill at too high of a speed during the hole drilling.

4. Use water to cool off the hot hole saw during the drilling process, in case the saw burns out.

5. On a 10mm thick piece of glass, the hole saw can create a maximum of 70-80 holes, though 4-50 is more recommended.

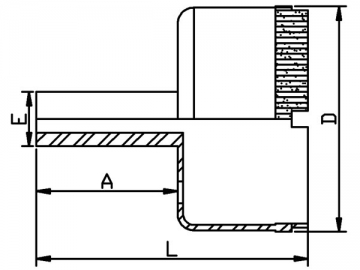

| Diamond drill bit | Straight shank |

| Length | 50mm |

| Diameter | 1.5-150mm |

Diameter (mm): 1.5-150

.jpg)