Multifunction Fluid Bed Dryer, TVP Series

Request a Quote

TVP series multifunction fluid bed dryer can perform functions of drying, top spray granulating and bottom spray coating through changing different bowls. The fluid bed dryer is manufactured in compliance with GMP requirements.

Samples

Features

- Wet granulation process offers high-efficiency granulation solution;

- Spray guns from world's renowned brands;

- Fluidized bed top spray granulation process is performed through the combination of air distribution plate and top spray gun, the liquid binder acts as a bridge to form granules which are featured by better bulk density and flow properties as well as good size distribution;

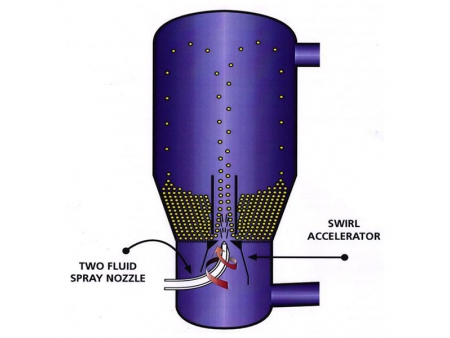

- Bottom spray coating (Wurster processing technology) can enables the coating to be uniformly applied because the spraying is in the same direction as the airflow;

- Reliable filtration system offers easy assembling and cleaning, multiple filtration methods are available to meet specific processing needs;

- PLC control, frequency converter, and industrial computer operation;

- Excellent process control system, with functions of management of formulation and process parameters, data logging, audit trail, electronic signature, etc.;

- The exhausted air flows through medium-efficiency and high-efficiency dust removal systems, enabling it can be directly discharged, meeting the requirements of environmental protection;

- WIP (wash-in-place) system;

- Optional 2-bar explosion pressure vent and 10-bar explosion-proof;

- Suitable for highly active substances, containment level of OEB4;

- Through-the-wall installation, high rate of space utilization for granulation;

Technical Specifications

- Model: TVP50

- Granulator effective volume (L): 60

- Granulator Capacity (kg/batch) (bulk density 0.5g/cm³): 7-20

- Total volume of coating (L): 50

- Coat capacity (kg/batch) (0.7g/cm³): 6-13

- Inlet air temperature control: Room temperature to 100℃

- Inlet air filtration: M6 F9 H13

- Medium efficiency dust collector for exhausted air: F9

- High efficiency dust collector for exhausted air: H13

- Fan power: 11

- Weight (t): 2.2

- Model: TVP75

- Granulator effective volume (L): 75

- Granulator Capacity (kg/batch) (bulk density 0.5g/cm³): 10-30

- Total volume of coating (L): 90

- Coat capacity (kg/batch) (0.7g/cm³): 10-20

- Inlet air temperature control: Room temperature to 100℃

- Inlet air filtration: M6 F9 H13

- Medium efficiency dust collector for exhausted air: F9

- High efficiency dust collector for exhausted air: H13

- Fan power: 15

- Weight (t): 2.5

- Model: TVP100

- Granulator effective volume (L): 100

- Granulator Capacity (kg/batch) (bulk density 0.5g/cm³): 15-60

- Total volume of coating (L): 280

- Coat capacity (kg/batch) (0.7g/cm³): 16-35

- Inlet air temperature control: Room temperature to 100℃

- Inlet air filtration: M6 F9 H13

- Medium efficiency dust collector for exhausted air: F9

- High efficiency dust collector for exhausted air: H13

- Fan power: 18.5

- Weight (t): 2.9

- Model: TVP200

- Granulator effective volume (L): 200

- Granulator Capacity (kg/batch) (bulk density 0.5g/cm³): 40-120

- Total volume of coating (L): 405

- Coat capacity (kg/batch) (0.7g/cm³): 50-80

- Inlet air temperature control: Room temperature to 100℃

- Inlet air filtration: M6 F9 H13

- Medium efficiency dust collector for exhausted air: F9

- High efficiency dust collector for exhausted air: H13

- Fan power: 22

- Weight (t): 3.5

- Model: TVP400

- Granulator effective volume (L): 400

- Granulator Capacity (kg/batch) (bulk density 0.5g/cm³): 60-200

- Total volume of coating (L): 460

- Coat capacity (kg/batch) (0.7g/cm³): 60-122

- Inlet air temperature control: Room temperature to 100℃

- Inlet air filtration: M6 F9 H13

- Medium efficiency dust collector for exhausted air: F9

- High efficiency dust collector for exhausted air: H13

- Fan power: 30

- Weight (t): 4

- Model: TVP600

- Granulator effective volume (L): 600

- Granulator Capacity (kg/batch) (bulk density 0.5g/cm³): 100-300

- Total volume of coating (L): 880

- Coat capacity (kg/batch) (0.7g/cm³): 115-230

- Inlet air temperature control: Room temperature to 100℃

- Inlet air filtration: M6 F9 H13

- Medium efficiency dust collector for exhausted air: F9

- High efficiency dust collector for exhausted air: H13

- Fan power: 45

- Weight (t): 4.6

- Model: TVP800

- Granulator effective volume (L): 800

- Granulator Capacity (kg/batch) (bulk density 0.5g/cm³): 120-400

- Total volume of coating (L): 880

- Coat capacity (kg/batch) (0.7g/cm³): 115-230

- Inlet air temperature control: Room temperature to 100℃

- Inlet air filtration: M6 F9 H13

- Medium efficiency dust collector for exhausted air: f9

- High efficiency dust collector for exhausted air: H13

- Fan power: 45

- Weight (t): 5.5

- Model: TVP1000

- Granulator effective volume (L): 1000

- Granulator Capacity (kg/batch) (bulk density 0.5g/cm³): 150-500

- Total volume of coating (L): 1000

- Coat capacity (kg/batch) (0.7g/cm³): 135-265

- Inlet air temperature control: Room temperature to 100℃

- Inlet air filtration: M6 F9 H13

- Medium efficiency dust collector for exhausted air: F9

- High efficiency dust collector for exhausted air: H13

- Fan power: 55

- Weight (t): 6

| Model | TVP50 | TVP75 | TVP100 | TVP200 | TVP400 | TVP600 | TVP800 | TVP1000 |

| Granulator effective volume (L) | 60 | 75 | 100 | 200 | 400 | 600 | 800 | 1000 |

| Granulator Capacity (kg/batch) (bulk density 0.5g/cm³) | 7-20 | 10-30 | 15-60 | 40-120 | 60-200 | 100-300 | 120-400 | 150-500 |

| Total volume of coating (L) | 50 | 90 | 280 | 405 | 460 | 880 | 880 | 1000 |

| Coat capacity (kg/batch) (0.7g/cm³) | 6-13 | 10-20 | 16-35 | 50-80 | 60-122 | 115-230 | 115-230 | 135-265 |

| Inlet air temperature control | Room temperature to 100℃ | |||||||

| Inlet air filtration | M6 F9 H13 | |||||||

| Medium efficiency dust collector for exhausted air | F9 | F9 | F9 | F9 | F9 | F9 | f9 | F9 |

| High efficiency dust collector for exhausted air | H13 | H13 | H13 | H13 | H13 | H13 | H13 | H13 |

| Fan power | 11 | 15 | 18.5 | 22 | 30 | 45 | 45 | 55 |

| Weight (t) | 2.2 | 2.5 | 2.9 | 3.5 | 4 | 4.6 | 5.5 | 6 |