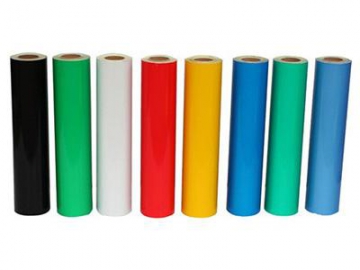

VCI Rust Prevention Sheeting

VCI rust prevention sheeting provides multifunctional anti-corrosion protection for ferrous metals and nonferrous metals during shipping and storage. It is an economical and highly efficient solution.

We are able to customize the rust prevention sheets into specific sizes according to customer needs, making it easy for customers to pack their metal products without risk of adhering to the metal and leaving a residue behind.

Advantages:

-An ESD antistatic agent is added to protect electronic components against static electricity.

-Effective corrosion protection and packaging combined in one step.

-Able to protect a variety of metals, saving time, money, and resources.

-Transparency - for clear visibility of packaged goods.

-Convenient to use, ready to apply right after removing them from the packaging

-Eco-friendly and recyclable

-Suitable for heat sealing.

Our products include standard VCI rust prevention sheeting and enhanced VCI rust prevention sheeting for heavy-duty applications.

Based on standard VCI rust prevention sheeting, we produce an enhanced VCI rust prevention sheeting to improve both the strength and the barrier characteristics by adding a fabric enhanced layer. Enhanced VCI rust prevention sheeting is suitable for packaging and sealing of metal products that require long term protection and storage, such as light and heavy duty products in metallurgy, machinery, appliances, aerospace, and shipbuilding industries, due to the high tensile strength and excellent shock resistance.

| Model | Type | Typical applications | Specifications |

| VCIF | Standard type | Rust preventive packaging for conventional metal parts | Customized according to customer specification (non-standard) |

| A-VCIF | Enhanced | Rust preventive packaging for high barrier requirements |

Type VCIF: Standard type VCI rust prevention sheeting

Thickness: 2μ~8μ;

Width: ≤3M

Type A-VCIF: Enhanced VCI rust prevention sheeting

Suitable for packaging and sealing metal products that require long-term protection and storage, such as light and heavy-duty products in metallurgy, machinery, appliances, aerospace, shipbuilding industry and more

Thickness: 2μ~10μ;

Width: ≤3M

Duration varies due to usage, environment, and packaged goods: normally between 5 months ~ 3 years

We can produce antistatic sheeting with an antistatic agent additive according to your specific needs.

Custom VCI rust prevention sheeting is available.

Custom patterns and logos available.

Cautions:

1. It is necessary to ensure that packaged products are clean and rust free, with no exposure to other corrosive chemical materials on the product surface before packaging.

2. During the packaging process, the temperature of packaged products and the surrounding environment should remain constant through the entire operation.

3. When packaged products are large-scale equipment, large box inner packaging or intensive products, we recommend using VCI material such as rust prevention paper, rust prevention bags, rust prevention powder and other rust prevention materials.

4. No barrier should exist between the packaged products and the rust prevention paper, such as a paper pad, protective bag or plastic board. It should also be noted that other paper types and wooden material should not come into direct contact with the packaged products.

5. Users wear gloves through the entire operation process in order to prevent corrosion caused by sweat or other skin oils.

6. The packaging antirust paper should not remain exposed to open air for long periods of time before use. After packaging, the packaging container should be sealed as soon as possible using a heat seal, adhesive tape, or cable tie. Any remaining anti-rust paper should be resealed in an enclosed space.