Twin Screw

Request a Quote

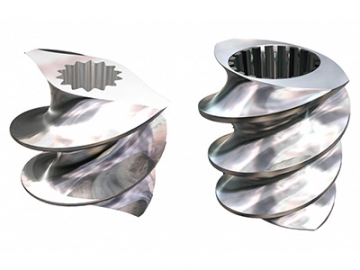

Twin screws are usually combined using several parts of different structures for a specific purpose. This particular type is often called a segmented screw. Omega provides custom made segmented screws and shafts in a specific size, even when that size is more than 10 meters. A few examples are shown below.

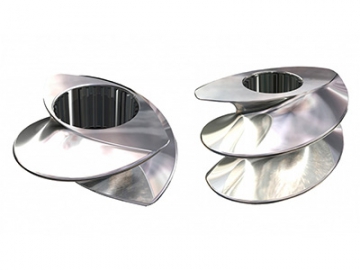

Conveying element

Conveying element Conveying element

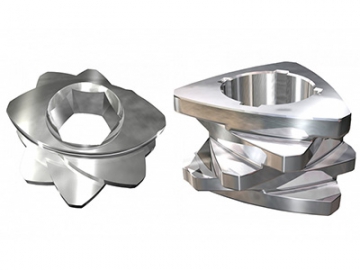

Conveying element Mixing element

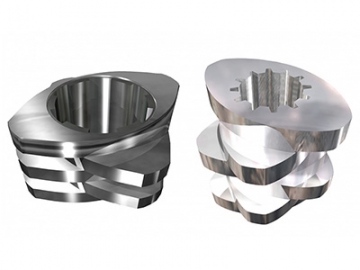

Mixing element Mixing element

Mixing element Mixer element

Mixer element

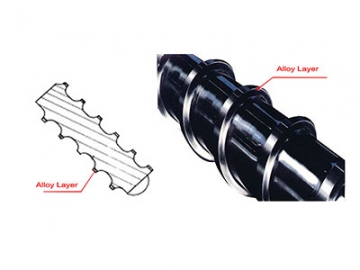

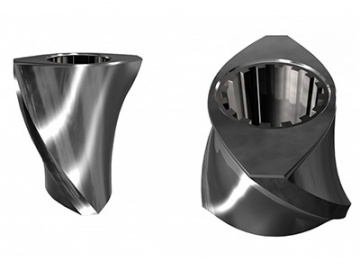

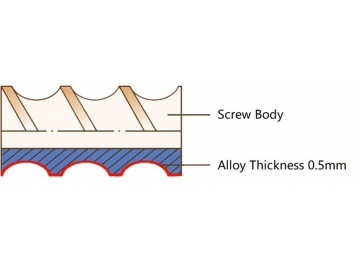

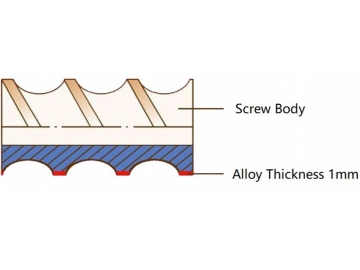

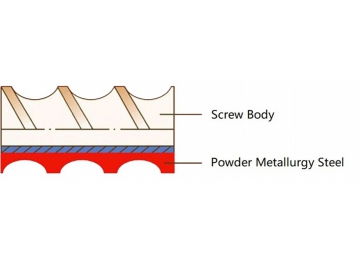

Omega applies alloy coating strategies to protect the surface of the twin screw from corrosion and abrasion caused by additives in engineering material and thermoplastic material. In doing so, the screw becomes much more durable. This screw type is known as a bimetallic twin screw.

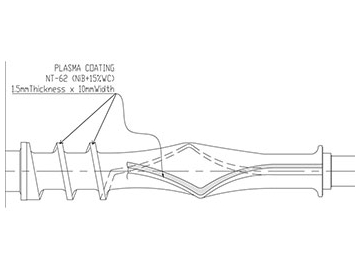

Three different types of bimetallic screws with different protection strategies are shown below.

All working face covered by alloy layers Flight covered by alloy layers

Flight covered by alloy layers The screw body with a driving function is made using a high toughness steel, and the flight is made using an powder metallurgy steel

The screw body with a driving function is made using a high toughness steel, and the flight is made using an powder metallurgy steel

Recommended materials for twin screw

WR5

W6M5Cr4V2(M2)

C12MoV(D2)

| Name | Material Type | Fe | C | Cr | Si | Mn | Mo | Ni | V | W | Hardness |

| WR 5 | Powder Tool Steel | Bal | 2.4~2.7 | 5.0~7.0 | 0.5~1.0 | ≤0.5 | 1.3~1.6 | -- | 9.0~10.0 | -- | HRC 60 ~ 64 |

| W6M5Cr4V2(M2) | High Speed Steel | Bal | 0.80 ~ 0.90 | 3.8 ~ 4.4 | 0.20 ~ 0.45 | 0.15 ~ 0.40 | 4.5 ~ 5.5 | ≤0.30 | 1.75 ~ 2.20 | 5.50 ~ 6.75 | HRC 60 ~ 64 |

| C12MoV(D2) | Die Steel | Bal | 1.45 ~ 1.70 | 11.0 ~ 12.5 | ≤0.40 | ≤0.40 | 0.4~0.6 | ≤0.25 | 0.15 ~ 0.30 | -- | HRC 58 ~ 60 |

Recommended materials for shaft

WR 30

45CrNiMoVA

40CrNiMoA(4340)

| Name | Material Type | Fe | C | Cr | Si | Mn | Mo | Ni | Other | Stand Torque Level |

| WR 30 | High Nitrogen Steel | Bal | 0.25 ~ 0.30 | 14.0 ~ 16.0 | 0.9 ~ 1.10 | 0.9 ~ 1.1 | 0.85 ~ 1.10 | 0.40 ~ 0.60 | N 0.3 ~ 0.5 | 11 Grade,L/D ≥48 |

| 45CrNiMoVA | High Torque Steel | Bal | 0.42 ~ 0.49 | 0.80 ~ 1.10 | 0.17 ~ 0.37 | 0.5 ~ 0.8 | 0.20 ~ 0.30 | 1.30 ~ 1.80 | V 0.1 ~ 0.2 | 9 Grade,L/D 48 |

| 40CrNiMoA(4340) | Torque Steel | Bal | 0.37 ~ 0.44 | 0.60 ~ 0.90 | 0.17 ~ 0.37 | 0.5 ~ 0.8 | 0.15 ~ 0.25 | 1.25 ~ 1.65 | -- | 8 Grade,L/D 36 ~ 48 |

Related products

Send Message

Most Recent

More

Other Products

Videos