PPR Pipe Fittings

Applications:

1. Hot & cold water piping systems for residential buildings, drinking-water supply piping, high purity water piping system

2. Piping system for industrial water and liquid chemicals

3. Beverage pipelines, drug delivery system

4. Compressed air piping

Parameters:

Product Description

Material: PP-R

Standard: CE, ISO9001, ISO14001: 2004

Pressure grade: PN 12.5-25MPa

Temperature: -40 ~ +95°C

Colors: White or customized

Connection: Welding

Technology: Hot welding machine

OEM: Available

Free sample: Support

Warranty: More than 50 years

Application: Hot and cold water

Equal socket

Reduce socket

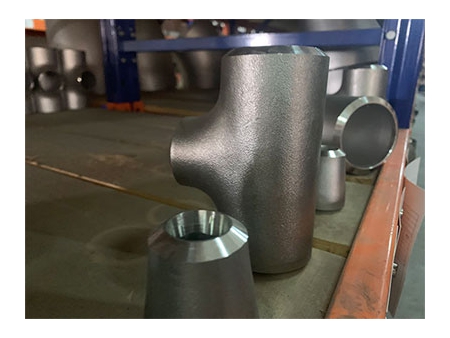

Equal tee

Elbow 45°

Elbow 90°

Reduce tee

Reduce elbow

End cap

Plug

Hold card

U type card

Female thread socket

Male thread socket

Male thread elbow

Male thread tee

Female thread tee

Female thread elbow

Conjoined bridge tee

Conjoined bridge elbow

Product features and technical parameters:

Polypropylene random copolymer features an outstanding weldability as the raw material for PPR pipes and fittings. These pipes and fittings are easily connected using heat fusion and electrofusion, and are easy to install with trusted connections. The strength of the pipe connections is often higher than that of the pipes themselves, ensuring there is no leakage.

PPR pipe fittings have a Vicat softening temperature (VST) of 131.5℃, and great thermal resistance. With a maximum operating temperature of 95℃, all requirements for hot water supply and water drainage systems in buildings are met.

Fenghe's PPR pipe fittings have a service life of more than 50 years at a working temperature of 70℃ and operating pressure of 1.0Mpa. If working at room temperature (20℃), these pipes feature a service life of more than 100 years.

Recommended product-special designed product

PPR pipe fittings, when paired with specially designed PPR pipes are both clear and concise, with a patented, ridged pipe fitting cover. As there are substances generated through a fusion process, the pipe fitting cover covers these materials, providing an attractive appearance for the pipe project. The grooves are used to determine if the fittings are installed correctly, as well as improve fitting strength. These grooves also add to the appearance, making the pipes appear diverse for different applications.