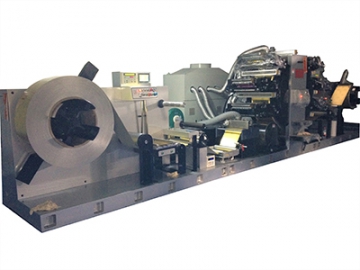

JX-4C460R+1 Flexographic Printing Press for Metal Printing

Jin Xiang’s metallic label printing machine with a flexo plate is capable of printing on any rolled up metal material, including aluminum, iron, and stainless steel. This flexographic machine not only performance printing on both sides of the substrates, but also features an excellent production efficiency.

We specially designed this 4-color flexographic machine for printing on metallic labels. The following detailed parameters are for reference only, and we are able to change equipment configurations or produce brand new equipment to meet customer requirements for printing effects and capacity.

| Model | 4 Color Flexographic Printing Press, JX-4C460 |

| Varnish station | 1 set |

| Gearing | 1/8" |

| Max. Web width | 460mm |

| Max. Print width | 450mm |

| Max. unwind width | 1600mm |

| Max. Rewind width | 1600mm |

| Max. Print length | 460mm |

| Min. Print length | 190.5mm |

| Print speed | 50m/min |

| Machine net weight | 1500kg |

| Machine gross weight | 2000kg |

| Power of main engine | 15kW, 380V |

| Motor power of ink dispenser (6pcs) | 420W |

| UV dryer | 37kW |

| Machine size (W×L×H) | 2×11×2m |

- Printing station (4 sets)

- Plate cylinder (5 sets, optional size)

- UV curing system(7 sets)

- Tension controller (2 sets)

- Tools (1 sets)

- Printing plate mounter (1 sets)

- Flexo plate proofer (1 sets)

- Splicing table (1 sets)

- Varnish unit (1 sets)

- Corona treatment unit (1 sets)

- Unwinder and rewinder (1 set respectively)

- Protective film laminator (1 sets)

- Cold foil unit

- Gravure printing unit

- Round screen printing unit

- Slitting and sheeting system

- Static observation system

- Cooling system

- Electrostatic eliminator

- Lamination unit and cross over unit for multi layer label production

- Tension control

The tension controller automatically adjusts the tension based on the material thickness. This allows the printing machine to handle printing on a variety of substrates with a thickness ranging between 0.05mm and 0.5mm.

- Servo technology

The ink feeding system in each printing station is controlled by a servo motor and CNC computer, ensuring an accurate ink feeding and feeding speed adjustment during the printing process.

- Corona treater

An advanced corona treater efficiently removes dust and increases ink adhesion on the printing substrates, making this machine applicable to printing on a variety of materials.

- Web guide controller

The web guide controller is equipped with web guider sensors to correct material later deviation in its forward motion, thus ensuring a printing accuracy.

Welcome to Dongguan Jinxiang Machinery Co., Ltd!

Please fell free to get in touch us through the inquiry form in this page and we will response as soon as possible and off the related service.