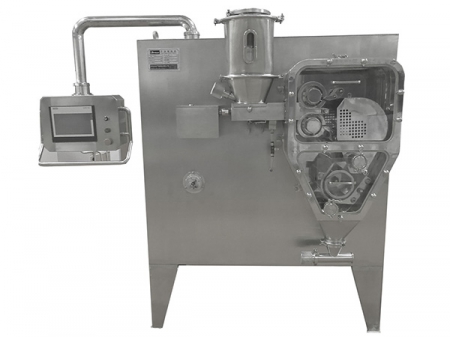

Dry Granulator (for Pharmaceutical and Food Industry)

The GZX model of dry granulators is developed using Germany technology. Compared to traditional dry granulators, the GZX model has a better granulation rate and is easier to clean.This roller compaction granulator is specially designed for the pharmaceutical and food industry, meeting GMP standards.

Features of the GZX Dry Granulator

1. Vertical feeding instead of conventional horizontal feeding.

2. Screw feeder feeds the raw material into rollers.

3. Rollers are easy to dissemble and clean.

4. Vertical layout of two rollers prevents raw material from falling.

5. Two levels of a sifting system increases granulation rate.

6. The granulator is closed operation, which prevents contamination from dust.

7. PLC and touch screen are optional.

Technical Parameters of the GZX Dry Granulator

| Model | ||||

| Width of roller (mm) | 100 | 120 | 150 | 180 |

| Effective width of roller (mm) | 90 | 110 | 140 | 170 |

| Diameter of roller (mm) | 229 | 239 | 249 | 259 |

| Max pressure of roller/width of roller | 21.3kn/cm | 21.3kn/cm | 21.3kn/cm | 21.3kn/cm |

| Thickness of pressed flake (mm) | 1-4 | 1-4 | 1-4 | 1-4 |

| Capacity (Kg/h) | 80-180 | 130-200 | 180-250 | 230-300 |

| Granule size | adjustable | adjustable | adjustable | adjustable |

| Productivity | 65%-75% | 65%-75% | 65%-75% | 65%-75% |

| Rotating speed of roller | adjustable | adjustable | adjustable | adjustable |

| Installation power (kw) | 15 | 18 | 22 | 28 |

| Weight (T) | 2 | 2.5 | 3 | 4 |

| Overall size (mm) (L*W*H) | 2100*1500*1800 | 2100*1500*1800 | 2100*1500*1800 | 2100*1500*1800 |