Automatic Biscuit Production Line

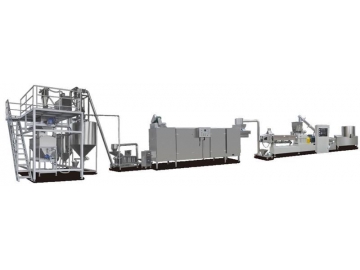

Introduction

Automatic biscuit production line produced by Luerya is designed to finish various processes including feeding, rolling, molding, waste recovery, drying, spraying and cooling automatically all at once. Luerya provides hundreds of molds and dozens of craft recipes to customers. They can produce all kinds of popular and high-grade cookies like butter cookies, sandwich biscuits, millet biscuits, ultra-thin biscuits, calcium milk biscuits, chocolate biscuit, soda biscuit, animal crackers, multivitamin biscuit, vegetables cookies and so on by changing molds and technical formulas.

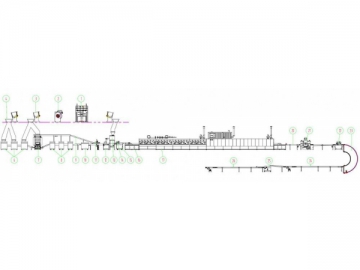

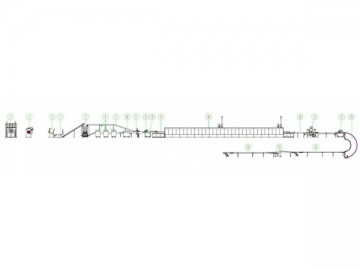

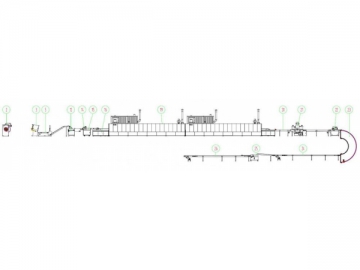

Equipment flowsheet

Flour mixer →cookie moulding machine→ Control cabinet → Oven → Oil injector → Cooler

| Model | Supply Voltage | Power | Throughput | Weight | Dimension | |

| DXB225 | 220V/380V 50Hz | 28.5KW | 50Kg/h | 1500kg | 18x0.6x1.5m | |

| DXB400 | 220V/380V 50Hz | 120KW | 100-180Kg/h | 2700kg | 45x0.8x1.5m | |

| DXB480 | 380V 50Hz | 160KW | 110-250Kg/h | 3300kg | 50x0.98x1.6m | |

| DXB600 | 380V 50Hz | 200KW | 180-500Kg/h | 4100kg | 80x1.1x1.75m | |

| DXB1000 | 380V 50Hz | 300KW | 100-180Kg/h | 5500kg | 100x1.85x2.45m |

Index

food processing equipment, commercial food machines, food manufacturing line, puffed food machines