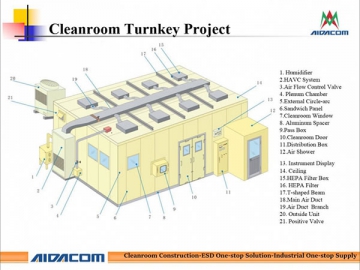

Cleanroom Production line

Aidacom is a premier expert in cleanroom design, production and installation. We can construct cleanrooms from class 100 to class 100,000 for electronics manufacturing, pharmaceutical production, optoelectronics assembly and many other different operations according to FS209E, GB50073-2001 and GMP requirements.

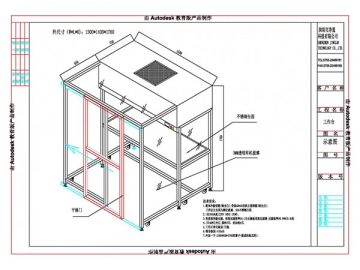

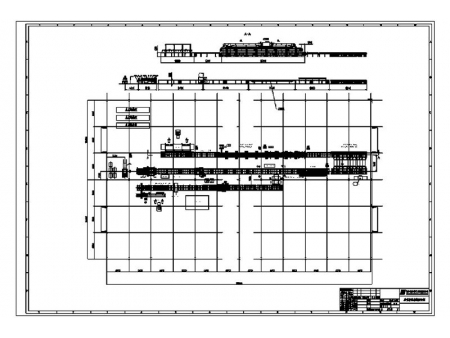

Cleanroom design is performed by our highly experienced and dedicated engineers and CAD drafters. They are equipped with advanced CAD software and we leave no details unconsidered. We can work with you in order to provide the best possible cleanroom solution within your budget.

1. Cleanroom Design and Construction

A. Cleanroom wall, ceiling, floor building

B. Cleanroom constant temperature and humidity HVAC system project

C. Cleanroom air system

D. Cleanroom lighting system

E. ESD production line design and assembly

F. ESD &cleanroom education and work position eSD document design

G. ESD &cleanroom consumables supply

2. Lab Design and Construction

A. Bio-safety lab

B. Ventilation system

C. Waste gas treatment system

D. Lab purification water system

E. Lab supply gas system

F. Lab wastewater disposal system

| Design (Engineering Scope) | Supply and Installation |

| Conceptual Design | Floor finish-PVC Flooring or Epoxy Resin Floor |

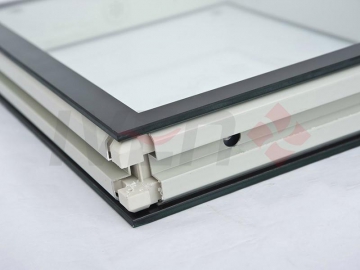

| Basic Design | Walls and Ceilings |

| Detailed Design | Ceiling HPL or Steel Panels (Customer choice) |

| RDS drafting | Wall HPL or Steel Panels (Customer choice) |

| FAT Support | Doors HPL or Steel Doors (Customer choice) |

| HVAC Drawings | HVAC |

| Personnel Flow Drawings | Hygienic Air Handling Unit(s)– GEA |

| Material Flow Drawings | Ductwork system |

| P&IDs DESIGN | Dampers TROX, |

| GMP Review | HEPA Filters & housings prepared for DOP TESTS |

| Ductwork Drawings / Capacities (pressure drops) | BMS (Building Management System) |

| Cleanroom Heat loads Review | Electrics |

| AHU Capacities Calculations | Lighting Supply |

| Pressure Cascades Calculations | Cleanroom Equipment |

| Cleanroom Classes/Grades Design Drawings | Clean Booth, Air Shower, Pass Box |

| BMS Drawings | Laminar Flow Clean Bench and Production Line |

| Project Schedule Drafting Project Supervision | Lab Fume Hood, ESD Equipment |

| Qualification(Test and Validation Scope) | |

| Commissioning / DQ / IQ / OQ / PQ | T&RH Tests |

| Balancing Cleanroom | Airflow Visualization Test |

| Commissioning Cleanrooms | Filter Integrity Tests |

| Airflows and Air changes Test | Particle Counting Tests |

| Differential Pressures Tests | Room Recovery Tests |