Automatic Chicken Nuggets, Chicken Strips, Colonel's Crispy Strips, Mcnugget Production Line

Introduction

Automatic chicken nuggets, chicken strips, Colonels Crispy Strips, McNugget production line uses minced meat as raw materials to make ready-to-eat chicken nuggets, chicken strips, fish finger. The processing procedures include forming, battering predust, tempura battering, breading and frying. The minced meat can be chicken meat, fish meat, seafood meat, beef, pork, lamb or even vegetables, such as potato or onion or beans. The shapes of final products can be changed easily, such as round, rectangle by changing the moulds.

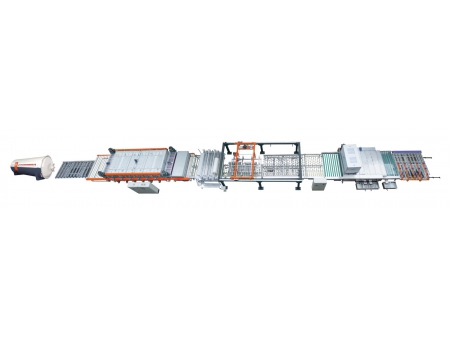

Specifications of Automatic Chicken Nuggets, Chicken Strips, Colonel's Crispy Strips, Mcnugget Production Line

| NO. | Processing Line Model | Capacity | Power | Area Requirement |

| 1 | LTNP-100 | 50-100kg/h | 2.77kw 30kw(fryer) | 8090*790*1480mm |

| 2 | LTNP-400 without fryer | 300-500kg/h | 20.35kw | 9650*1615*2200mm |

| 3 | LTNP-600 without fryer | 500-1000kg/h | 24.75kw | 10025*1815*2200mm |

Components of Automatic Chicken Nuggets, Chicken Strips, Colonel's Crispy Strips, Mcnugget Production Line

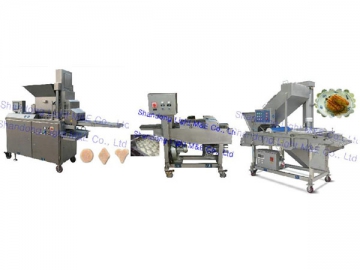

1. Automatic Forming Machine

2. Battering Machine

3. Preduster

4. Tempura Battering Machine

5. Continuous Fryer

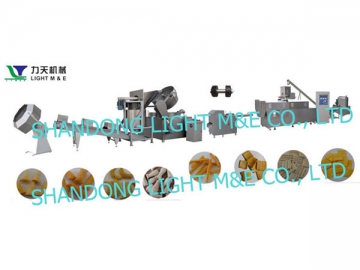

We are a major manufacturer of automatic chicken nuggets, chicken strips, colonel's crispy strips, Mcnugget production line in China. We are devoted to providing complete snack food processing machinery and full set of equipment to the clients.

In addition to Mcnugget production line, we can also produce pellet snack machinery, frying snack extrusion machinery and food extruder, etc. If you have any need, please feel free to contact us.