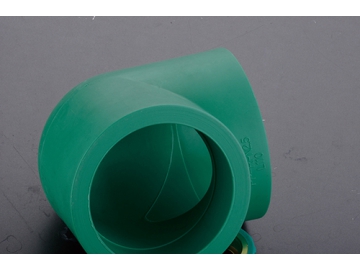

PPR Piping System

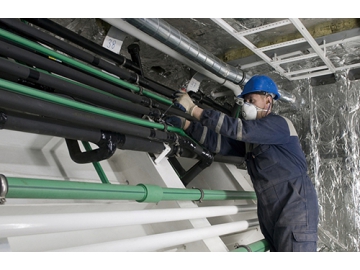

The Heim-Weh-GmbH has developed one of the latest PPR piping systems on the market. The environmental friendly plastic pipes and pipe fittings go through special production processes. For more than 20 years, our PP-R piping systems have demonstrated excellent technical practicality in various applications around the world. The PPR piping system is recognized by experts as one of the most widely used and best quality plastic piping systems in the world.

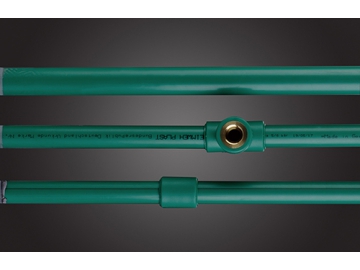

PN1.25: Φ20×2.0, Φ25×2.3, Φ32×3.0, Φ40×3.7, Φ50×4.6, Φ63×5.8

PN1.6: Φ20×2.3, Φ25×2.8, Φ32×3.6, Φ40×4.5, Φ50×5.6, Φ63×7.1

PN2.0: Φ20×2.8, Φ25×3.5, Φ32×4.4, Φ40×5.5, Φ50×6.9, Φ63×8.7

PN2.5: Φ20×3.4, Φ25×4.2, Φ32×5.4, Φ40×6.7, Φ50×8.3, Φ63×10.5

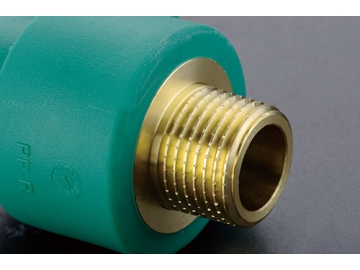

The PP-R pipe conforms to European standards for drinking water transport (Brass pipe, nickel-chromium-free).

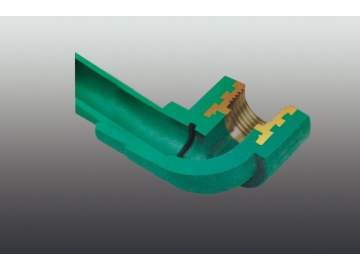

- Better corrosion resistance: Copper pipe fittings are made of lead-free environmentally friendly copper, which has better corrosion resistance compared to common brass.

- Colorless and odorless: The PP-R pipe does not produce irritating odors when hot melted.

- Good corrosion resistance: The PP-R pipe does not have any chemical effect on all ions in water and chemicals in buildings.

- The PP-R pipe has excellent temperature resistance and pressure resistance

- The PP-R pipe has low flow resistance and no fouling

PP-R raw materials supplier: Borealis

PP-R raw materials supplier: Borealis Use of lead-free environmentally friendly copper

Use of lead-free environmentally friendly copper Made in Germany

Made in Germany Injection molding process

Injection molding process

- ISO 14001 Environmental Management System Certification

- ISO 9001 Quality Management System Certification

- Aenor Certification

- WRAS Product Approval Certification

- Certificate of Conformity

- SKZ Certificate

- DVGW (German Technical and Scientific Association for Gas and Water) certificate

- KIWA Certificate

| Melt flow index (g/10min) | Density (g/cm3) | Compressive stress (MPa) | Tensile stress (MPa) | Elongation at break(%) | BrinellHardness (N/mm2) | Impact strength (KJ/m2) | Vicatsoftening temperature (℃) | Melting range (℃) | Linear expansion coefficient (1/k) | Thermal conductivity (W/m·k) | Longitudinal shrinkage (%) | |

| Testing value | 0.3 | 0.898 | 25 | 850 | >50 | 48 | 130(10N) 61(50N) | 150-160 | 1.5x10(-4) | 0.24 | < 2 | |

| Testing standard | ISO1133 condition 12 | ISO1183 | ISO527/1.2 | ISO527/1.2 | ISO37 | ISO2039/1 | ISO179/1eu | ISO306/A-B | DSC | DIN53752 | DIN52612 | GBT6671- 2001-B |

| Testing condition | 230℃/ 2.16kg | +23℃ | 50mm/min | 50mm/min | 132N/30s | 23 0 -10℃ | 10N 50N | 135±2℃ |

The excellent thermal stability and purity of PP-R materials are two of the biggest advantages of these systems. The PP-R material's physical and chemical properties are suitable for potable water and heating systems. More importantly, the material's good welding and melting properties allow for permanent integral connection.

- Mark the insertion of the pipe. (Equal to the insertion depth of the joint).

- The surface of pipes and joints should be stable, clean and oil-free.

- Heat the entire insertion depth, including pipes and joints in the welding tool.

- Connect the pipe and joint.

- When the heating time is completed, smoothly and evenly push the pipe into the joint to form a firm and perfect combination.