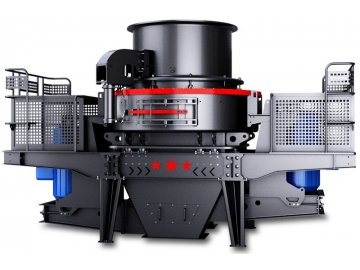

Vertical Shaft Impact Crusher

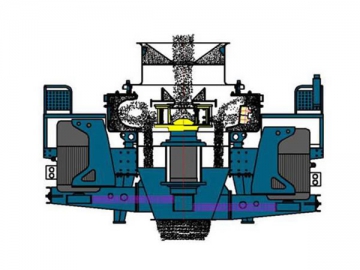

Our VSI impact crusher has many advantages. First of all, it has a sophisticated and patented feed system, which divides raw materials into two parts through the lining plate attached to the feed hopper. One part will directly enter a high speed spinning rotor and the other will fall surrounding the lining plate. In this way, the rotor is able to throw the stone against the stone falling and the anvils that line the outside of the crushing chamber. The action of stone striking stone fractures the materials efficiently and reduces wear significantly at the same time. Secondly, advanced hydraulic opening device adopted makes it easy to replace wearing parts in the interior of the crushing chamber. Thirdly, the diluted oil lubrication system in the double oil pump allows for smooth operation of the base bearing. Last not the least, the crusher is able to stop automatically or give out a warning massage once its high-tech automatic monitor detects something wrong.

Application

1.VSI crusher has proven its effectiveness in production of artificial aggregate and stone reshaping industry. It is suitable for production of various kinds of aggregates from raw materials including cobble, hill-stone such as limestone, granite, basalt, diabase and andesite, tailings and aggregate chips. To be more specific, these aggregates constitute construction aggregate, pavement surface material, cushion material, asphalt concrete aggregate, and cement concrete aggregate.

2. In engineering filed, it is able to provide aggregates for construction of hydrop ower projects, high-grade highways, expressways, high speed railways, passenger railway lines, bridges, airport pavements, public facilities and high-rise buildings.

3. In mineral industry, the crusher is capable of conducting fine crushing in the first section of ore grinding. It also plays an important role in material crushing in various areas such as construction materials industry, metallurgical industry, chemical industry, mining industry, fireproofing materials industry, cement industry and highly abrasive materials industry.

4. Moreover, the crusher is suitable to work in secondary crushing process.

5. Furthermore, the crusher can be used for sulphur removal in thermal power industry and metallurgical industry, thus protecting the environment. It is also able to reduce the size of steel slags and construction wastes so that they can be easily disposed of or recycled.

6. In addition, the crusher can be adopted for production of glass, quartz sand and other high-purity materials.

| Model | Capacity (t/h) | Best Feed Size (mm) | Rotating Speed (r/min) | Double-Motor Power (kw) | Dimension (L×W×H)(mm) | Weight (t) | Power Supply | Vibration Sensor | Oil Dilution and Lubrication Station | |||||

| Feed at Center and All Sides | Feed at Center | Soft Material | Hard Material | Double-Pump Motor Power | Safety Device | Dimension L×W×H(mm) | Oil Tank Heater Power | |||||||

| 120-180 | 60-90 | 35 | 30 | 1700-1890 | 110 | 3700×2150×2100 | 11.8 | 380V, 0Hz | Monitoring Range: 0.1-20mm/s continuously adjustable | 2×0.25KW | Two oil pumps are able to replenish each other to ensure enough oil supply. They will stops automatically once no oil flow and no oil pressure is detected. Cool water is used to cool oil pumps when required. In winter, we start oil pumps after heating the motors. | 820×520×1270 | 2KW | |

| 200-260 | 100-130 | 40 | 35 | 1520-1690 | 180 | 4140×2280×2425 | 14.5 | |||||||

| 300-380 | 150-190 | 45 | 40 | 1360-1510 | 264 | 4560×2447×2778 | 17.8 | |||||||

| 450-520 | 220-260 | 50 | 45 | 1180-1310 | 400 | 5000×2700×3300 | 25.6 | |||||||