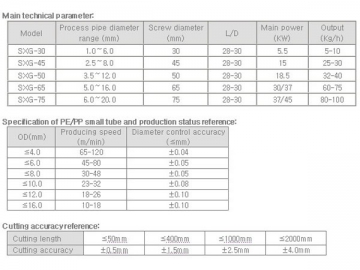

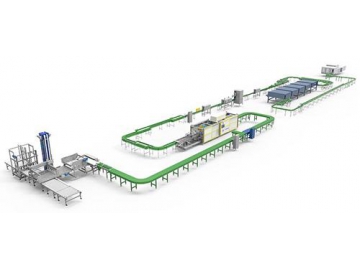

PE,PP precision tube extrusion line

PE Precision Tube Extrusion Line / PP Precision Tube Extrusion Line / Automatic Precision Tube Extrusion Line

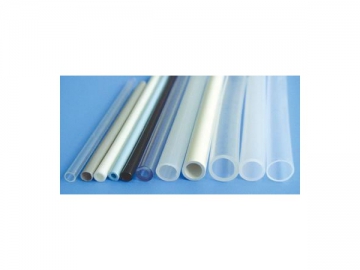

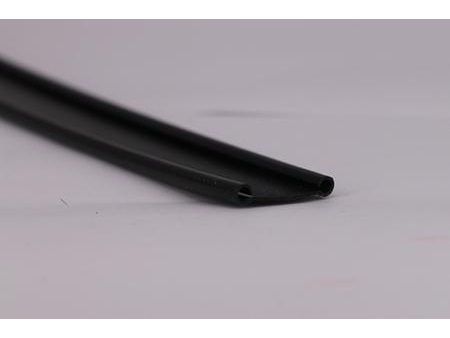

The applications for the PE and PP precision tube extrusion line include the production of spray heads for cosmetics and cleaning products, straw tubes, porous filter pipes, and ball point pen ink refills, just to name a few. Different pipe diameters and hardness ranges can be customized just by changing the combination of equipment further down the line.

Equipment Features

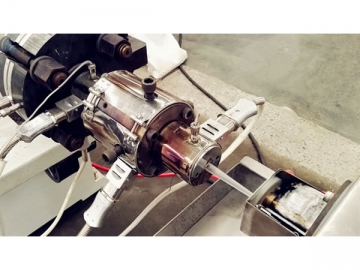

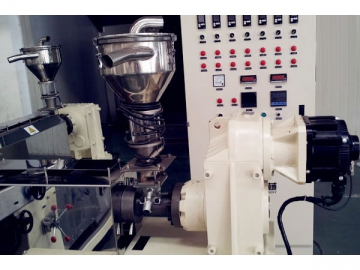

The highly automatic PE and PP precision tube production line is equipped with a specially designed high pressure positive displacement die to ensure a precise, stable and high speed extrusion.

Using a newly developed vacuum control technology, the vacuum and water system are separately controlled, with the vacuum accuracy /- 0.1Kpa

The precision tube extrusion line uses a high performance LaserMike measuring system, forming a closed-loop feedback control to eliminate diameter deviation online.

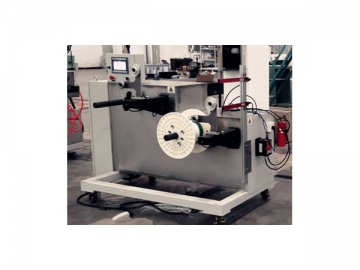

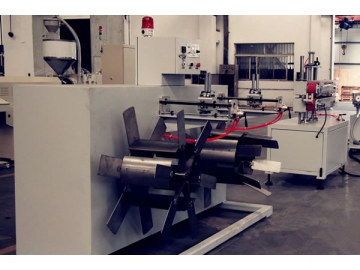

The puller uses an imported multi-layer composite wearable strap that meets medical sanitary requirements. It is a high level precision roller, and the servo motor drive offers a high stability pulling performance.

The cutter uses a servo system that offers a high speed and highly accurate cutting action. With a Mitsubishi PLC programmable control and SIEMENS human to computer interface, the cutter can achieve continuous cutting, timing of the cutting length count for cutting and other functions. The cutting length can be freely set, and counting is done automatically in order to meet different cutting length requirements.