Wood Pulp Molding Machine

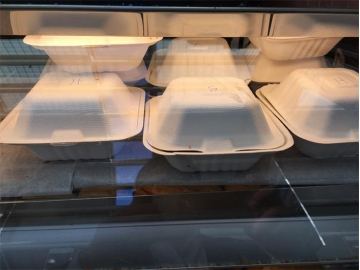

Wood pulp molding machine takes wood pulp as its primary raw material, produces microwavable, freezable and distillable food packaging products including plates, bowls, trays, cups and mugs. It can also produce industrial packaging products.

- Plate

Bowl

Bowl Box

Box Tray

Tray Cup

Cup

We provide the following 6 models. Different molds can be chosen to produce different pulp products. Click to view details.

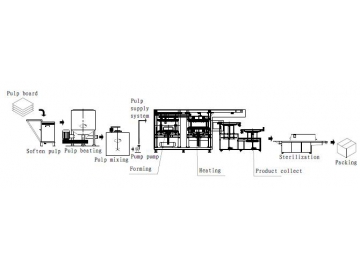

Manufacturing Process Detail

1. Pulping process takes soaked paper pulp boards and mixes them into pulp. Paper boards are mixed by hydraulic pulper and taken into pulp mixing pool. After adding eatable waterproof, oil proof additives, they are taken into pulp feeding pool.

2. Pulps are slip casted, stirred evenly with water and then dehydrated. Formed product and then moved to solidifying mold for further dehydration.

3. Formed products are transported to drying mold by negative pressure.

4. No further trimming process is needed after heating. Products can be directly sterilized and packaged.

The production line consists of an automatic pulp molding machine, a forming pool, a trim-free unit, hydraulic solidifying drying unit, an optic fiber alarming unit, a transferring unit, a collecting unit, a hydraulic unit, and a PLC control system.