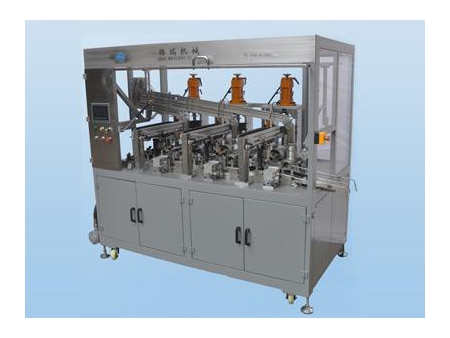

High Speed Tube Filler and Sealer, ZHF-160

Aluminum / Plastic Tube Filling Machine, Automatic Tube Filling and Sealing Machine, Auto Tube Filler, Automatic Tube Filling and Sealing Line

Features

1. The transmission system of the auto tube filling and sealing machine is sealed and set under the working platform to avoid pollution

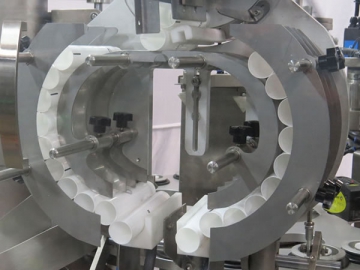

2. The tube filling and sealing system is mounted in a semi-closed static-free visual enclosure for easy observation, manipulation, as well as maintenance

3. Stainless steel switches are prepared for operating the panel

4. Optional inclined-hanged or vertical-hanged tube storage

5. A vacuum suction device is mounted for the tube filler & sealer to let the tubes enter the feeding system automatically

6. We use the photoelectric sensor, the high-precision probe, as well as the stepper motor to determine the tubes’ position

7. After filling, the air blower will blow off the paste end automatically

8. No material will be extruded if there is no tube

9. The automatic tube filling and sealing equipment is designed to heat the inner wall of tube end with Leister heat-air generator at the same time cool the outer side

10. The printing device prints the codes automatically on the prescribed position

11. Either right-angle or round-corner shapes of the tube ends are available with a manipulator

12. Failure alarming & over-loading stopping mechanism is adopted

13. Tube counting and auto-stopping mechanism

Technical Parameters of the Auto Tube Filling & Sealing Line

Production efficiency: 160 tubes /min (max)

Filling volume: 1-300 ml

Filling precision: ≤±0.5%

Tube length: 50-240 mm

Tube diameter: 10-50 mm

Power supply: 380V, 50Hz / 220V, 60Hz

Power of hot-wind generator: 3kw

Compressed air consumption: 1.2 m3

Working pressure: 0.6 MPa

Hopper volume: 70L

Dimensions: 2870×1770×2340 mm

Allowable tube types: metal tubes, plastic composite tubes, or aluminum plastic composite tubes

Applications

Zhonghuan auto filling and sealing machine is an ideal for products that use soft tubes as the packaging containers. It is widely accepted in industries like cosmetics, household chemical, pharmacy, and food. We have designed it to fill the ointments, creams, gels, and other viscous liquids into tubes automatically.