UHMWPE Marine Fender Pad

Request a Quote

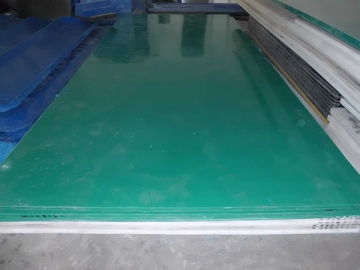

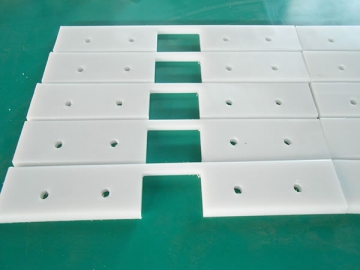

Our marine fenders are UHMWPE parts produced using a sintering process either from unused or reclaimed material (aprox. 70% reclaimed 30% new material - also called double-sintered or blended UHMWPE).

Advantages of the UHMWPE Marine Fender

Ultra high impact strength

Very low friction coefficient

Extremely high abrasion resistance

Standard Colors

Black, Yellow, Blue, Green, Red, and White.

(Other colors are available upon request)

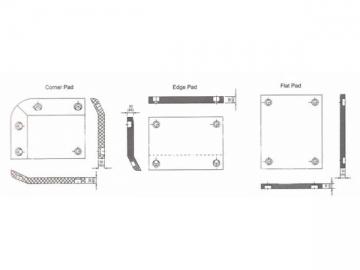

Applications of the Plastic Fender

Low resistance sliding plates on fender panels

Low resistance sliding panels for bridge and pier protection

Corner protection for offshore structures, berths, and other marine facilities

| Item | Test method | Unit | UHMWPE 1000-V | UHMWPE 1000-DS |

| Density | ISO1183-1 | g/cm3 | 0.93-0.95 | 0.95-0.96 |

| Yield Strength | ASTM D-638 | N/mm2 | 15-22 | 15-22 |

| Breaking Elongation | ISO527 | % | >200% | >100% |

| Impact strength | ISO179 | Kj/m2 | 130-170 | 90-130 |

| Abrasion | ISO15527 | Steel=100 | 80-110 | 110-130 |

| Shore Hardness | ISO 868 | Shore D | 63-64 | 63-67 |

| Friction Coefficient(Static state) | ASTM D-1894 | <0.2 | <0.2 | |

| Operating temperature | - | ℃ | -80 to 80 | -80 to 80 |

For special designs for UHMWPE marine fender or custom UHMWPE panels, please contact us by email.

Related products

Send Message

Most Recent

More

Other Products

Videos