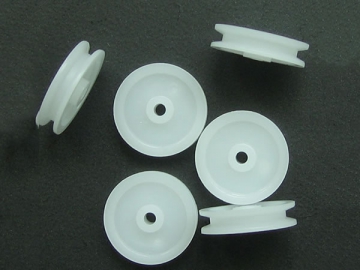

UHMWPE Pulley/Roller

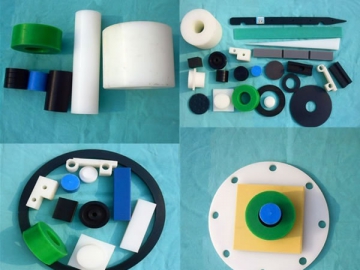

UHMWPE rollers are excellent quality high-tech engineering plastic components. Manufactured using ultra-high molecular weight polyethylene, these rollers are more wear resistant and have better rotation performance compared to metal or ceramic idler rollers. They feature the following advantages:

1. UHMWPE machined parts boast a linear flexible molecular structure, low surface hardness, and low friction coefficient self-lubricating properties. These features extend the life of the belt 1-2 times longer than metal or ceramic rollers.

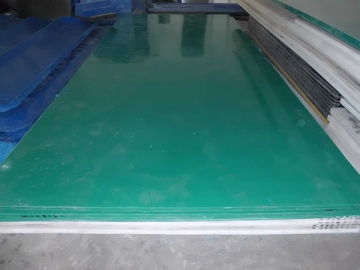

2. Corrosion and weather resistant to protect the engineered plastic rollers from rain, snow, acid, and alkali liquids.

3. UHMWPE has anti-adhesion properties even when exposed to water and oils. Dirt and dust resistant.

4. Antistatic properties.

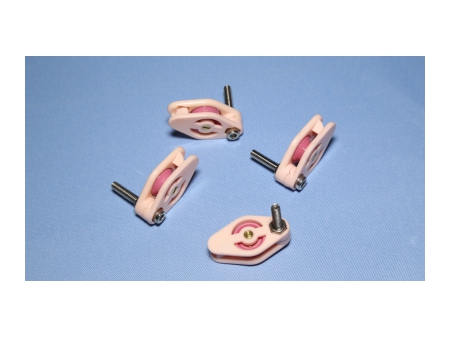

1. Wear Resistance

UHMWPE pulley's wear resistance is extremely high. The usual device for testing the wear resistance of common plastic pulley is not suitable for UHMWPE pulley because its performance is too high to accurately measure. UHMWPE’s wear resistance increases with its molecular weight.

2. Impact Resistance

UHMWPE pulley has the highest impact strength among all common machined plastic parts. The impact strength increases along with molecular weight.

3. Smoothness

The UHMWPE pulley has a very low friction coefficient (0.05-0.11). Its excellent dynamic friction factor in water is half that of PA66 and POM under the same conditions.