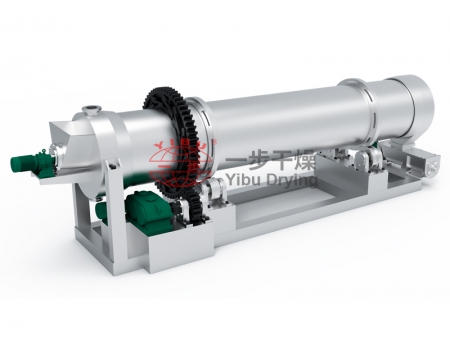

Drum Dryer

The GT model rotary drum dryer is an indirect heating dryer in continuous production. Raw material is fed into the top or bottom of the drum and sticks to the side. Steam or thermal oil fills the inside of the drum, which then transfers heat to dry the raw material. The dried product, in flake form, will be scraped from the insides and crushed before being transported out by a screw conveyor. Evaporated moisture will be sucked out by an exhaust fan.

The grain dryer is best for drying liquid raw material or sticky material in the chemical industry, dye industry, pharmaceutical industry, food industry, and metallurgy industry.

Features

1. High efficiency. As almost all of the heat is used for the drying process, drying efficiency reaches as high as 80-90%.

2. Widely used. The pigment dryer can dry raw material with a wide range of moisture content. The user can get the best drying effect by adjusting the feed rate, thickness of pavement, drum rotating speed, feeding form, etc.

3. Short retention time. Drying time only takes 10-15 seconds and the pharmaceutical dryer can process heat sensitive material.

Technical Parameters of the GT Drum Dryer

| Specification / Parameter | ø800×600 | ø1000×2000 | ø1200×2000 | ø1400×2400 | ø1600×2400 |

| Driving motor power (kw) | 3 | 4 | 5.5 | 7.5 | 11 |

| Heating area (m2) | 1.5 | 6.2 | 7.5 | 10.5 | 12 |

| Rotating speed of drum (r/min) | 0.5-5 | ||||

| Heating source | Thermal oil, steam, hot water | ||||

| Feeding form | Up or down | ||||

| Note | Please note if you use steam as a heating source. | ||||