Foam Cutter (Vertical CNC Contour Cutting Machine, Model GV6)

Uses

The contour cutting machine can cleanly cut any wanted geometric profile, which can then be used in the automotive industry, furniture industry, packaging industry, building industry, and daily usage industries.

Cutting Materials

Elastic PUR foam, PUR rebond foam, PE, EVA, EPP, polyester, reticulated foam, melamine foam, rubber rebond foam, adhesive and thinning material, mineral wool, fibrous non-woven fabrics, cloths and fabrics.

| Standard | Option | |

| Length of the foam block | 3000mm | 4500mm/5000mm |

| Height of the foam block | 1250mm | 1500mm |

| Width of the foam block | 2200mm | 2300mm |

| Worktable | Conveyor-type worktable | |

| AC power | 380V 3 phase 4 wire | |

| Total power | 25KW | |

| Max. feeding speed | 40m/min | |

| Cutting precision | ±0.5mm | |

| Cutting tool | Air pressure: 6 bar Continuous blade Blade size: 10350mm×3.5mm×0.6mm Line speed: 10-15m/s | |

| Standard configuration | Remote diagnosis and maintenance Automatic programming software Automatic sharpening and dust collection devices Crossbeam Absolute value control Automatic angle adjustment Automatic edge finding | |

| Optional configuration | Automatic press roller Loading conveyor (with lifting) L3300mm Unloading conveyor (with lifting) L3300mm | |

| Max cutting speed | Different cutting materials will be cut at different speed. And the max. speed is 60 meters/minute. | |

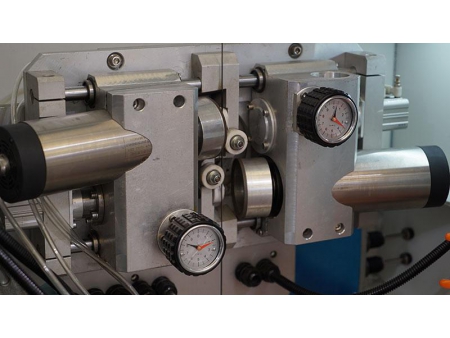

Here is our GV6 foam cutter. The vertical CNC contour cutting machine uses a computer control system and a high speed, continuous knife. This knife cuts max speed is 60m/min, and cuts cleanly, emitting no dust. This CNC foam cutting machine cuts foam automatically according to a preset designed path.

Our contour cutting machine’s operating system is reliable, and is capable of processing foam blocks of any size and most materials, such as memory foam and cleaning foam. It is functional and easy to use, while still performing quietly and efficiently, with a great looking final product. The efficient contour cutting machine is useful for a variety of foam production needs, and has been a first choice for contour cutting in the foam industry.

The CNC foam cutter has been upgraded from the G1, and its major improvements include a faster cutting speed while maintaining a high precision, enhancing production efficiency. The machine design itself is different, and is more compact and elegant than the G1.

Cutting directionInstallation instruction