Triangular Pattern Self-Cleaning Screen

Request a Quote

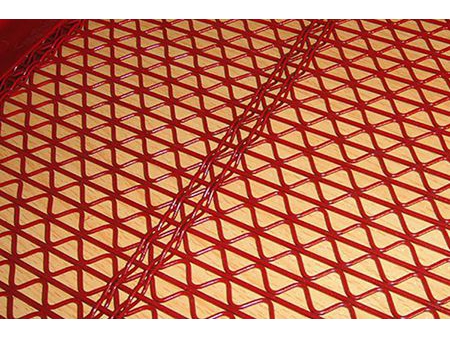

Anti-clogging mesh with triangle-shaped openings

DUNPAI’s triangular pattern self-cleaning screens have triangle-shaped meshes, making them suitable to carry out fine screening at scale. Thanks to the shapes, the self-cleaning wire screens feature marvelous load capacity, while ensures a long service life, three times longer than that of common mining screens with square-shaped apertures. The triangular-pattern screens are applicable not only in mining industry, but also in hot-mix asphalt plants, making them absolutely a cost-effective choice for you.

- Self-cleaning screen with triangular mesh is suitable for very fine materials with high load bearing capacity;

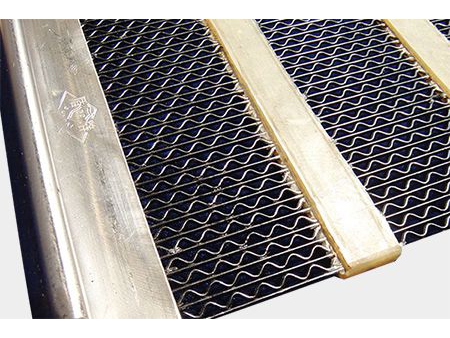

- Triangular openings formed by alternating straight and crimped wires for better impact absorption;

- Rubber or polyurethane cross bands are optional to strengthen the screening surface and vibration stability;

- Can last up to three times longer than common screens;

- Especially suitable for hot-mix asphalt plants;

- Excellent performance when accurate sizing is required;

- Opening: 5/64 inch – 7/8 inch;

| Aperture Width (mm) | Wire Diameter(mm) | Wire Diameter (inch) | Weight/m2 | Opening Area | Material |

| 2.00 | 1,20 - 1,60 | 3/64” - 1/16” | 4,3 - 6,3 | 43 - 36 | AR/AISI 304/AISI 316 |

| 2.50 | 1,20 - 2,00 | 3/64” - 5/64” | 3,8 - 8,0 | 49 - 37 | AR/AISI 304/AISI 316 |

| 3.00 | 1,20 - 2,00 | 3/64” - 5/64” | 3,5 - 7,6 | 54 - 38 | AR/AISI 304/AISI 316 |

| 3.50 | 1,20 - 1,60 | 3/64” - 1/16” | 3,4 - 5,4 | 56 - 47 | AR/AISI 304/AISI 316 |

| 4.00 | 1,20 - 2,50 | 3/64” - 0,098 | 3,0 - 9,2 | 60 - 42 | AR/AISI 304/AISI 316 |

| 4.50 | 1,50 - 2,50 | 0,059 - 0,098 | 4,0 - 7,5 | 58 - 46 | AR/AISI 304/AISI 316 |

| 5.00 | 1,50 - 2,80 | 0,059 -7/64” | 3,9 - 9,1 | 59 - 45 | AR/AISI 304/AISI 316 |

| 5.50 | 1,50 - 2,50 | 0,059 - 0,098 | 3,0 - 6,7 | 65 - 52 | AR/AISI 304/AISI 316 |

| 6.00 | 1,50 - 3,15 | 0,059 -1/8” | 3,0 - 10,7 | 66 - 45 | AR/AISI 304/AISI 316 |

| 6.30 | 2,50 - 2,80 | 0,098 -7/64” | 7,4 - 8,2 | 52 - 51 | AR/AISI 304/AISI 316 |

| 6.50 | 2,00 - 2,50 | 5/64” - 0,098 | 5,1 - 6,2 | 59 - 56 | AR/AISI 304/AISI 316 |

| 7.00 | 2,00 - 3,15 | 5/64” -1/8” | 4,0 - 11,6 | 64 - 47 | AR/AISI 304/AISI 316 |

| 7.50 | 2,00 - 2,50 | 5/64” - 0,098 | 5.50 | 60 | AR/AISI 304/AISI 316 |

| 8.00 | 2,00 - 4,00 | 5/64” -5/32” | 4,4 - 10,9 | 65 - 50 | AR/AISI 304/AISI 316 |

| 8.50 | 2,00 - 2,50 | 5/64” - 0,098 | 5.10 | 64 | AR/AISI 304/AISI 316 |

| 9.00 | 2,00 - 3,15 | 5/64” -1/8” | 4,8 - 7,7 | 65 - 58 | AR/AISI 304/AISI 316 |

| 9.50 | 2,50 - 2,80 | 0,098 -7/64” | 6.10 | 62 | AR/AISI 304/AISI 316 |

| 10.00 | 2,00 - 3,15 | 5/64” -1/8” | 4,7 - 7,8 | 66 - 60 | AR/AISI 304/AISI 316 |

| 11.00 | 2,80 - 3,15 | 7/64” -1/8” | 6.70 | 64 | AR/AISI 304/AISI 316 |

| 11.50 | 2,50 - 3,15 | 0,098 -1/8” | 5.9 | 66.0 | AR/AISI 304/AISI 316 |

| 12.00 | 2,50 - 4,00 | 0,098 -5/32” | 4,0 - 9,0 | 72 - 60 | AR/AISI 304/AISI 316 |

| 12.50 | 2,50 - 4,00 | 0,098 -5/32” | 5,6 - 8,3 | 68 - 62 | AR/AISI 304/AISI 316 |

| 13.00 | 2,00 - 3,15 | 5/64” -1/8” | 3,7 - 6,7 | 73 - 65 | AR/AISI 304/AISI 316 |

| 14.00 | 2,80 - 4,00 | 7/64” -5/32” | 5,2 - 7,7 | 70 - 65 | AR/AISI 304/AISI 316 |

| 15.00 | 2,80 - 4,00 | 7/64” -5/32” | 4,4 - 7,3 | 73 - 67 | AR/AISI 304/AISI 316 |

| 16.00 | 3,00 - 4,00 | 0,118 -5/32” | 5,9 - 8,6 | 70 - 65 | AR/AISI 304/AISI 316 |

| 17.00 | 3,00 - 4,00 | 0,118 -5/32” | 6.70 | 69 | AR/AISI 304/AISI 316 |

| 18.00 | 3,00 - 4,00 | 0,118 -5/32” | 6,4 - 8,0 | 71 - 68 | AR/AISI 304/AISI 316 |

| 19.00 | 3,00 - 4,00 | 0,118 -5/32” | 6.20 | 72 | AR/AISI 304/AISI 316 |

| 20.00 | 3,00 - 4,00 | 0,118 -5/32” | 3,2 - 7,5 | 79 - 70 | AR/AISI 304/AISI 316 |

| 21.00 | 3,00 - 4,00 | 0,118 -5/32” | 5.70 | 74 | AR/AISI 304/AISI 316 |

| 22.00 | 3,00 - 4,00 | 0,118 -5/32” | 5,6 - 8,2 | 74 - 70 | AR/AISI 304/AISI 316 |

| 23.00 | 3,00 - 4,00 | 0,118 -5/32” | 5.70 | 75 | AR/AISI 304/AISI 316 |

| 24.00 | 3,00 - 4,00 | 0,118 -5/32” | 5,7 - 7,1 | 74 - 71 | AR/AISI 304/AISI 316 |

| 25.00 | 3,00 - 4,00 | 0,118 -5/32” | 5,5 - 6,6 | 75 - 73 | AR/AISI 304/AISI 316 |

| 26.00 | 4,00 - 4,00 | 5/32” - 5/32”” | 6.50 | 74 | AR/AISI 304/AISI 316 |

| 30.00 | 4,00 - 5,00 | 5/32” - 13/64” | 5,4 - 8,0 | 78 - 74 | AR/AISI 304/AISI 316 |

Triangular pattern self-cleaning screens offer unique advantages in various scenarios and material applications, primarily in terms of anti-clogging properties, improved screening efficiency, and extended service life.

- Mining industry: Commonly used for handling large particle size materials in ore screening, such as coarse ore screening, sizing screens, and material classification.

- Construction materials: Frequently used for screening construction materials like sand and gravel, including the screening of sand, stone, coal, and concrete aggregates.

- Agriculture industry: Can be used for screening grains, seeds, and agricultural by-products.

- Chemical industry: Applied for screening chemical powders, catalysts, and coating particles.

- Food processing industry: Widely used for screening powdered materials such as flour, sugar, seasonings, and milk powder.

- Environmental protection industry: Particularly effective in separating different types of solid waste during garbage sorting or waste separation.

- AISI 304L / EN 1.4307: Austenitic stainless steel with low carbon content.

- AISI 304 / EN 1.4301: High resistance austenitic stainless steel.

- AISI 316 / EN 1.4401: Austenitic stainless steel with molybdenum to strengthen corrosion resistance.

- AR / EN 10270: Wear resistant steel with a high content of carbon and manganese.

- NUBA Screening Media, at the customer’s request can provide a Quality Inspection Certificate (compliant with EN 10204.3.1.B) showing the chemical and mechanical properties of the materials. Other Aperture/wire combinations and materials such as galvanized steel etc. are available at customer’s request.