Get in touch with us

Tandem Press Brake

Request a Quote

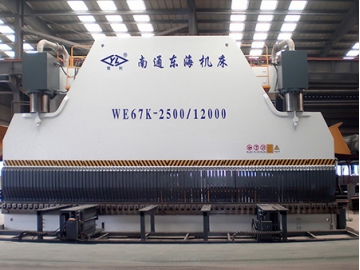

Tandem press brake is typically designed for extra-long workpiece bending applications by utilizing two or more press brakes in tandem with synchronized control system.

Features

- Precision bending to provide a superior processing accuracy;

- The motion of sliding block is controlled by four hydraulic cylinders; Electro-hydraulic servo system is used to control the four cylinders for sliding block synchronization, ensuring a constant reliability;

- Using CNC controller from world famous brand DELEM to control Y-axis;

- Manual operation, semi-automatic operation and fully automatic operation are available;

- Back gauge is controlled by high performance servo motor, ensuring high positioning accuracy of X-axis;

- Coupled with CNC control, worktable is outfitted with automatically adjustable deflection compensation system and V-axis to ensure high accuracy of workpiece processing;

- REXROTH electro-hydraulic servo valve is characterized by compact structure, high synchronization precision, long service life;

- Adopting HYTECH high pressure gear pump which can bear high pressure and produce low noise;

- Overflow protection is outfitted to hydraulic system;

- The tandem press brake can be continuously operated under rated workload condition, and the hydraulic system is featured by high stability without leakage problem, significantly guaranteeing a high precision;

- Various specifications including open height (daylight), throat depth and quantity of CNC axis are selectable according to your specific needs;

Applications

Details

DA-52S CNC control system

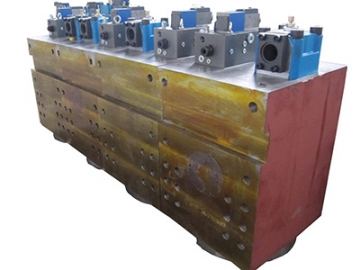

DA-52S CNC control system  Hydraulic cylinder

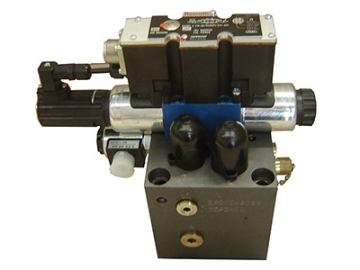

Hydraulic cylinder  Proportional servo valve

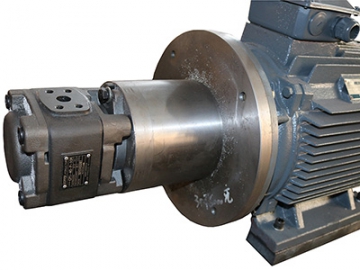

Proportional servo valve  Motor & pump

Motor & pump  Front in-feed unit

Front in-feed unit  Back gauge

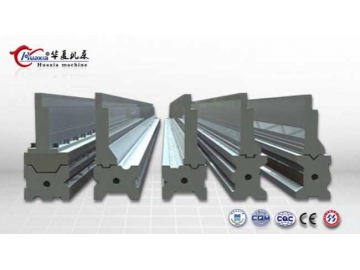

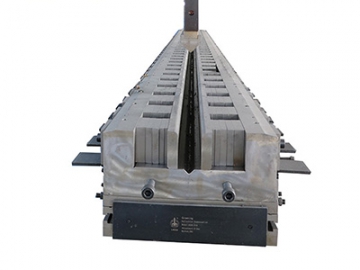

Back gauge  Adjustable bottom die

Adjustable bottom die  Side out-feed unit

Side out-feed unit

Optional configurations

DA-66T CNC control system

DA-66T CNC control system  Cooling system

Cooling system  Suction pad lifting system

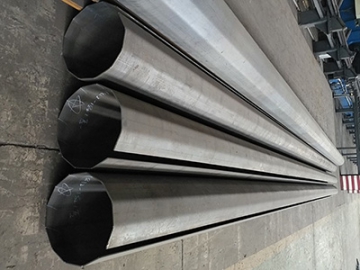

Suction pad lifting system  Round light pole tooling

Round light pole tooling

Specifications

| No. | Model | Unit | 2xWE67K-200/4000 | 2xWE67K-300/4000 | 2xWE67K-400/4000 | 2xWE67K-500/4100 | 2xWE67K-500/6000 | 2xWE67K-600/6000 |

| 1 | Nominal force | KN | 2x2000 | 2x3000 | 2x4000 | 2x5000 | 2x5000 | 2x6000 |

| 2 | Length of working table | mm | 2x4000 | 2x4000 | 2x4000 | 2x4100 | 2x6000 | 2x6000 |

| 3 | Distance between uprights | mm | 3100 | 3100 | 3100 | 3100 | 4800 | 4800 |

| 4 | throat depth | mm | 320 | 350 | 400 | 400 | 1300 | 1300 |

| 5 | Max. daylight | mm | 435 | 435 | 520 | 600 | 1300 | 1300 |

| 6 | Main motor power | KW | 2x15 | 2x22 | 2x30 | 2x37 | 2x45 | 2x45 |

| 7 | Main oil pump | L/min | 2x25 | 2x40 | 2x50 | 2x63 | 2x80 | 2x80 |

| 8 | Approaching speed | mm/s | 70 | 70 | 70 | 70 | 70 | 70 |

| 9 | Bending speed | mm/s | 7 | 7 | 7 | 7 | 7 | 7 |

| 10 | Returning speed: | mm/s | 70 | 70 | 70 | 70 | 70 | 70 |

| 11 | Length | mm | 2x4200 | 2x4200 | 2x4200 | 2x4400 | 2x6200 | 2x6200 |

| 12 | Width | mm | 1650 | 1850 | 2000 | 2400 | 2800 | 3000 |

| 13 | Height(over land) | mm | 3070 | 3285 | 3430 | 3710 | 4300 | 4600 |

| No. | Model | Unit | 2xWE67K-600/7000 | 2xWE67K-800/6000 | 2xWE67K-800/6500 | 2xWE67K-800/7000 | 2xWE67K-1000/6000 | 2xWE67K-1200/7000 | 2xWE67K-1600/6000 | 2xWE67K-1600/7000 |

| 1 | Nominal force | KN | 2x6000 | 2x8000 | 2x8000 | 2x8000 | 2x10000 | 2x12000 | 2x16000 | 2x16000 |

| 2 | Length of working table | mm | 2x7000 | 2x6000 | 2x6500 | 2x7000 | 2x6000 | 2x7000 | 2x6000 | 2x7000 |

| 3 | Distance between uprights | mm | 5600 | 4800 | 4800 | 5600 | 4800 | 5600 | 4800 | 5600 |

| 4 | Throat depth | mm | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 |

| 5 | Max. daylight | mm | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 |

| 6 | Main motor power | KW | 2x45 | 2x2x37 | 2x2x45 | 2x2x37 | 2x2x45 | 2x2x45 | 2x2x55 | 2x2x55 |

| 7 | Main oil pump | L/min | 2x80 | 2x2x50 | 2x2x63 | 2x2x50 | 2x2x63 | 2x2x80 | 2x2x100 | 2x2x100 |

| 8 | Approaching speed | mm/s | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 |

| 9 | Bending speed | mm/s | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 |

| 10 | Returning speed: | mm/s | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 |

| 11 | Length | mm | 2x7200 | 2x6200 | 2x6700 | 2x7200 | 2x6200 | 2x7200 | 2x6200 | 2x6300 |

| 12 | Width | mm | 3000 | 3500 | 3500 | 3500 | 3800 | 4000 | 4500 | 4500 |

| 13 | Height(over land) | mm | 4600 | 4800 | 4800 | 5000 | 5100 | 5800 | 5900 | 5900 |

Related products

Send Message

Most Recent

More

Other Products

Videos