PE Pipes and Fittings (for Water Supply)

Here at Kingbull, we are proud to offer wide specifications of PE pipes and fittings for water supply piping systems. The flexibility of polyethylene pipes allows cost savings in installation. In addition, they can be supplied in straight lengths or in coils, thus reducing the need for joints and fittings.

Application Water Supply System

Water Supply SystemFeatures of the PE Pipes and Fittings

1. Great flexibility, excellent resistance to low temperature;

2. Outstanding resistance to environmental stress cracking, ensuring slow cracking speed;

3. Jointed using electronfusion techniques, ensuring perfect sealing performance and strong loading capacity;

4. Smooth inner wall, reducing resistance to water flow;

5. Anti-corrosion, high sanitary performance;

6. Light weight, making the plastic pipes and fittings easy for handling and installing.

Specifications of the PE Pipes and Fittings

PN1.6Mpa | 20×2.3 | PN1.25Mpa | 200×14.7 | PN0.8Mpa | 160×7.7 |

| 25×2.3 | 250×18.4 | 200×9.6 | |||

| 32×3.0 | 315×23.2 | 250×11.9 | |||

| 40×3.7 | 355×26.1 | 315×15 | |||

| 50×4.6 | 400×29.4 | 355×16.9 | |||

| 63×5.8 | PN1.0Mpa | 75×4.5 | 400×19.1 | ||

| 75×6.8 | 90×5.4 | 450×21.5 | |||

| 90×8.2 | 110×6.6 | 500×23.9 | |||

| 110×10.0 | 125×7.4 | 560×26.7 | |||

| 125×11.4 | 160×9.5 | 630×30.0 | |||

| 160×14.6 | 200×11.9 | PN0.6Mpa | 110×4.2 | ||

| 200×18.2 | 250×14.8 | 125×4.8 | |||

| 250×22.7 | 315×18.7 | 160×6.2 | |||

| 315×28.6 | 355×21.1 | 200×7.7 | |||

| 355×32.2 | 400×23.7 | 250×9.6 | |||

| 400×36.3 | 450×26.7 | 315×12.1 | |||

| SDR 13.6 PN1.25Mpa | 63×4.7 | 500×29.7 | 355×13.6 | ||

| 75×5.6 | 560×33.2 | 400×15.3 | |||

| 90×6.7 | 630×37.4 | 450×17.2 | |||

| 110×8.1 | PN0.8Mpa | 90×4.3 | 500×19.1 | ||

| 125×9.2 | 110×5.3 | 560×21.4 | |||

| 160×11.8 | 125×6.0 | 630×24.1 |

Colors: Blue, BlackPE Pipe Fittings

-

PE 45° Elbow -

PE100 90° Elbow, PN08L110 -

PE100 Equal Tee, PN1.25T110 -

Eight-Way

-

45° Elbow -

45° Elbow -

Elbow -

Plastic Flange -

Male Threaded Elbow -

Tail -

Reducer, 63×50 -

Reducer, 90×32 -

Reducing Tee -

Reducing Tee, 63×50 -

Taper -

22.5° Elbow, Butt Weld -

Cross, Butt Weld

Advantages:

1. Premium Raw Materials

Kingbull’s PE pipes are made using PE100 materials which account for high pipe strength and great resistance to environmental stress cracking. The PE100 materials that we use are from Yanshan Petrochemical, Shanghai Petrochemical, Jilin Petrochemical, etc.

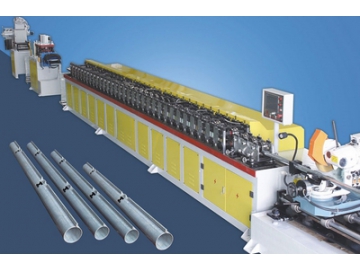

2. Production Equipment

1) We introduce Barton Heidfeld and Krauss-Maffei extruders which feature high production efficiency and great stability. With memory function, they ensure the stable quality of pipes.

2) BM barrier screw and IKV forced feed system are applied. They make for remarkable solid-liquid separation, great plasticizing effect, small pressure and temperature fluctuation, high speed and stable extrusion at low temperature and low material loss.

3) Advanced Electric Fusion Welding Machine

a. Automatically identify fittings and conduct auto setting of welding process;

b. Operation tip, voltage and current monitoring in the whole process;

c. Automatic temperature compensation