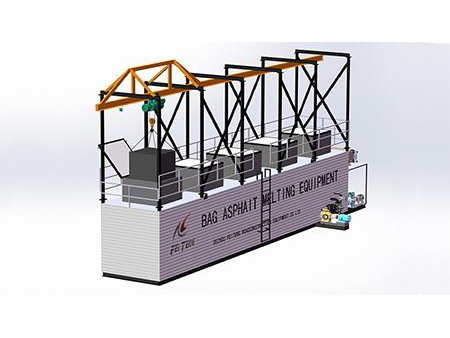

YDLR Series Bag Asphalt Melting Equipment

Request a Quote

Feiteng YDLR Series bag asphalt melting equipment is specially designed for the melting and heating of 1 ton bag asphalt. The outside shape is square tank. The top of the equipment is equipped with a electric hoist. The bag asphalt is lifted by the hoist to the feeding port at the top of the equipment. The bottom bag is cut by knives, then the asphalt block in the bag is taken out and dropped into the equipment through the feeding port to be heated. There are 5 feeding ports, each port will be with one movable lid for insulation and rain proof.

Technical Parameters

| Item | Parameter |

| Production capacity (t/h) | 8-10 |

| Diesel consumption (kg/t) | 6-8 |

| Asphalt output temperature (℃) | >110℃ |

| Asphalt storage capacity (m³) | >30 |

| Thermal oil working temperature(℃) | 200-250 |

| Asphalt pump flow rate(㎡/h) | 16 |

| Total power(kw) | ≤15 |

| Outer size(length*width*height) (m) | 11.9×2.2×2.55 |

Features

- The equipment integrates the thermal oil boiler with the heating device, diesel burner as the heating source, diesel as the fuel, imported Italy brand Baltur as oil burner, the performance is stable, full combustion, high thermal efficiency and no pollution. And the asphalt heating temperature can be controlled automatically without manual inspection.

- The equipment integrates the thermal oil boiler with the heating device, diesel burner as the heating source, diesel as the fuel, imported Italy brand Baltur as oil burner, the performance is stable, full combustion, high thermal efficiency and no pollution. And the asphalt heating temperature can be controlled automatically without manual inspection.

- The middle part of the tank body is provided with the thermal oil coil. The input asphalt block is quickly melted and cut into small pieces and then falls into the lower melting tank, which is equipped with dense thermal oil coils and high-temperature flue at the bottom. The small asphalt block is further heated and melted into a liquid state and reaches a temperature that can be smoothly pumped out.

- The start-up and shut of burner is automatically controlled by two temperature controllers, equipped with asphalt temperature sensor and a thermal oil temperature sensor, each temperature sensor corresponds to a digital display temperature controller. The digital form visually displays the current measured temperature and set temperature. The temperature of the thermal oil and the asphalt can be set freely according to the production demand. When the temperature of the asphalt or thermal oil reaches the upper set limit, the burner automatically stops, when the temperature of the asphalt and the thermal oil is lower than the low set limit, the burner is automatically started. The asphalt heat is controlled by the automatic digital controller, and no manual inspection.

- Two temperature control modes, auto-mode and manual mode, manual mode is prepared in case of auto mode failure.

- The thermal oil circulation pump and the diesel burner have interlocking function: the precondition of the diesel burner working is that the thermal oil circulation pump is in the working state, and the diesel burner automatically stops when the thermal oil circulation pump stops working unexpectedly.

- The melted asphalt is pumped out to the asphalt storage tank by the asphalt pump for storage or further heating.

It has an internal circulation function of asphalt, that is, one end of asphalt is pumped from the other end to promote the circulation and to accelerate the melting speed. - The asphalt pump is equipped with an asphalt filter to filter out impurities in the asphalt.

- The bag asphalt melting equipment has equipped with ladders and top guardrails.