Frequency Inverter (for Construction Hoists), AS620 Series

Request a Quote

AS620 Series

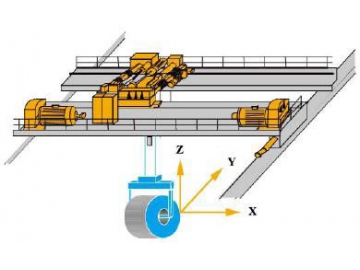

The AS620 series of frequency inverters for construction hoists is designed for elevator drive applications. This high end inverter uses leading motor control technology for reliable, flexible and safe operation. Our customizable frequency inverters are mainly used for industrial cranes and hoisting.

Features

1. PWM dead zone compensation technology reduces loss of motor

2. Low-inductance bus technology for safety

3. Multiple frequency settings

4. Automatic slipping compensation adjustable depending on load and motor speed

5. Jumping frequency control function

6. AFR function: when grid voltage changes, the same output current is maintained

Special functions for elevators

1. Several options for VF curves

2. Counter and anti-counter torque and fixed torque startup

3. Safe and reliable AFR functions

4. Brake control functions

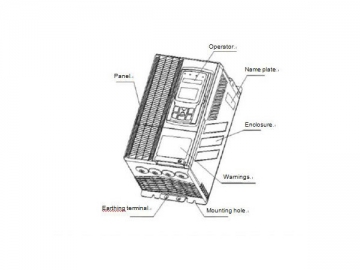

Reliable product design

1. Independent air duct design

2. Compact structure

3. Wide voltage range

4. Power on self-check function

5. Terminal protection

6. Overheating alerts

| Power input | Input power | 380V~460V (-15%~ 10%), 3-phase power supply |

| Input frequency | 45~65Hz | |

| Permissible voltage variation | Voltage unbalance factor < 3% | |

| Transient voltage dips | For 3-phase AC 380V~460V power supply, when input voltage < AC300V, under-voltage protection after 15ms |

| Power output | Motor output voltage | 0VAC~100% input voltage, 3-phase power supply |

| Output frequency | V/F control: 0.00~300.00Hz | |

| Overload class | 150%, 60s | |

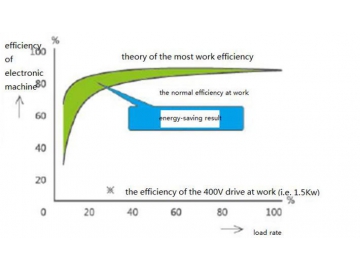

| Efficiency (full load) | > 94% | |

| Accuracy of output frequency | ±0.01% (digital instruction -10~ 45℃ ) ±0.1% (analog instruction 25±10℃ ) |

| Digital input/output | Photocoupler isolation input | 8-way, 24V high/low effective level is settable. Input functions are definable. |

| Open collector output | 6-way. Output functions are definable. | |

| Relay output | 2-way. NO and NC double contacts, contact capacity: resistive, 5A 250VAC or 5A 30VDC; output functions are definable. |

| Analog input/output | Analog voltage input | 2-way, -10~ 10 VDC or 0~ 10 VDC, accuracy 0.1% |

| Potentiometer voltage | Provide 10VDC power (maximum 25mA) for setting speed |

| Control characteristics | Control method | V/F control |

| Startup torque | 2.50Hz 150% | |

| Range of speed regulation | 1:50 | |

| Accuracy of speed control | ±2%; obtain ±0.5% accuracy under slip compensation | |

| Carrier frequency | 2~10k (Hz) | |

| Frequency setting resolution | 0.01Hz (digital instruction) ±0.06Hz/120Hz (analog instruction 11bit unsigned) | |

| Operation command channel | Operation panel given, control terminal given, communication given | |

| Frequency given channel | Operation panel given, digital/analog given, communication given | |

| Torque boost | Automatic torque boost; manual torque boost | |

| V/F curve | User-defined V/F curve, linear V/F curve and 5 kinds of drop torque characteristic curves | |

| Automatic voltage regulation (AVR) | Regulate the duty cycle of output PWM signal automatically according to the fluctuation of bus voltage so as to relieve the effect on the output voltage fluctuation by fluctuation of the grid voltage. |

Related products

Send Message

Most Recent

More

Other Products

Videos