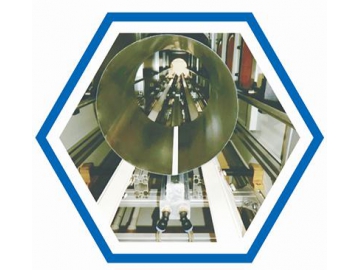

Curing System

The curing system is used to dry and solidify the welding line's coating. Our curing oven has a user-friendly design interface, which supports use in both Chinese and English. It also has a detailed fault display and requires very little maintenance.

Structural Features: This metal can making machinery has a specially designed magnetizer cross-section that concentrates the heating area within the range of 20mm welding lines. Our curing system effectively achieves power saving technology, control of the magnetic field’s direction, reduction of the external magnetic field’s radiation, as well as quick and uniform heating. The aluminum sealed enclosure effectively reduces the electric field’s radiation, and the unique refrigeration design of the air duct improves the service life of the curing system.

Control System: The control parts and heating parts are run separately, which not only improves the curing system's performance stability, compatibility and anti-jamming, but it is also conducive to future expansion to meet production needs. The external and internal protection circuits of our industrial oven can guarantee a better normal work level and extend the service life.

There are 50 levels available to have fine settings in the curing system's power adjustment. The power output is automatically controlled by the PWM according to the load size. The drying oven's heating time curve can be flexible, based on process requirements.

Technical Parameters| Curing Length | 4m /6m/8m/10m/12m/14m/16m/18m/20m |

| Feeding Speed | 15-60m/min (Stepless Speed Regulation) |

| Diameter of Can | Ø 52- Ø180mm |

| Max. Power | 1.5kw/ Burner |

| Output Frequency | 20--30KHz |

| Voltage | 380V,3Phase |

| Cooling Mode | Wind cooling |

| Temperature Performance | 0-500 ℃ |