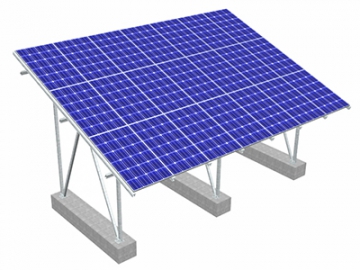

GT4 Ground Mount Solar Panel Racking System

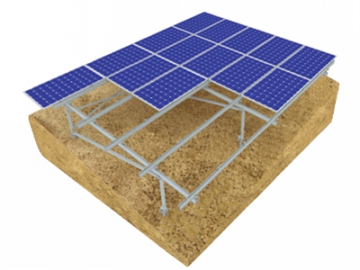

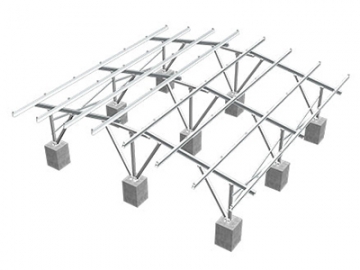

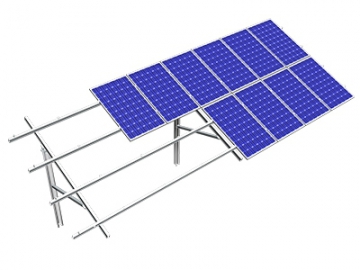

The MRac GT4 solar ground mounting system is applicable for large photovoltaic power plants which typically have higher requirements for handling snow and wind. The square tube post in the GT4 solar racking system adopts a T anchoring base plate. The GT4 solar ground mounting system has fewer accessories, therefore, there is no need for cutting or punching hole on site, which make installation more efficient and saves construction costs. The rail in the GT4 solar racking system adopts our self-developed clamp to connect to the solar panel which makes punching holes unnecessary. This kind of design make the press direction match the force direction of the solar racking system, which improves the mechanical strength of the solar racking system.

- Ground-Mounted System

- Mounting Angle

- Ground Clearance :500~2000mm

- Applicable Solar Panels: framed panels & frameless panels

- Solar Panel Layout: horizontal panel installation & vertical panel installation

- Quality & Warranty

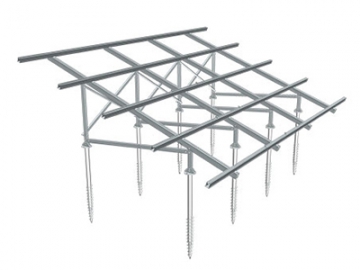

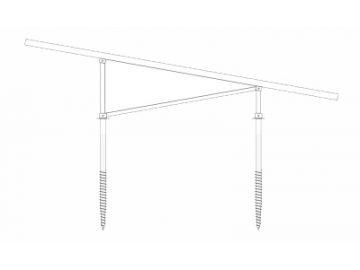

GT4-N preassembled rack structure

GT4-N preassembled rack structure

| Mount Location | Ground | Design Standard | AS/NZS 1170 , DIN 1055 ,JIS C8955 2017 , |

| Mount Base | Concrete Foundation, Ground Screw Foundation | International Building Code IBC 2009 | |

| Mount Angle | 0-60° | California Building Code CBC 2010 | |

| Wind Load | 60m/s | Rack Material | Al6005-T5 (Surface Anodic Oxidation) |

| Snow Load | 1.6KN/m2 | Fastener Material | Zn-Ni Alloy & Stainless Steel SUS304 |

| Ground Clearance | 500-2000mm | Mounting Accessories Material | Al6005-T5 (Surface Anodic Oxidation) |

| Applicable Solar Panels | Framed Panels & Frameless Panels | Column color | Natural Silver or According to Customer |

| Solar Panel Layout | Horizontal Panel Installation & Vertical Panel Installation | Warranty Period | 15 years |

- TUV Test

- Patent

- AS NZS 1170 Certificate

- SGS Material Analysis

- ISO 9001 Certification

- SAAEA

1.C clamp kit 2.End clamp 3.U25 Mid Clamp 4.Rail 85 5.Splice for Rail 85 6.T Anchoring Base Plate

The GT4 solar ground mounting system provides four types of preassembled rack structure to meet client requirements.

- W Shaped preassembled rack

- Multiple-element rack I

- Multiple-element rack II

- Multiple-element rack III