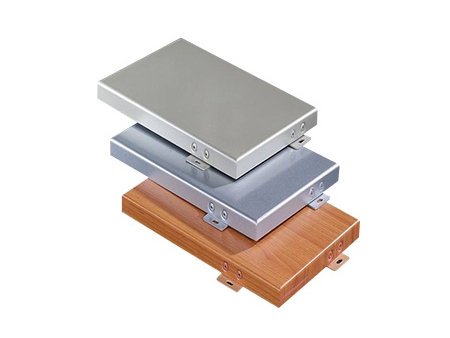

Digital UV Printing Aluminum Composite Panel, ACP Panel

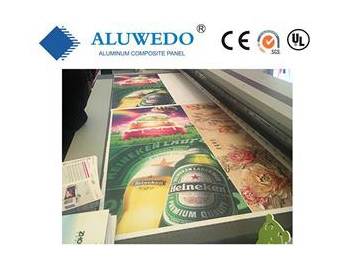

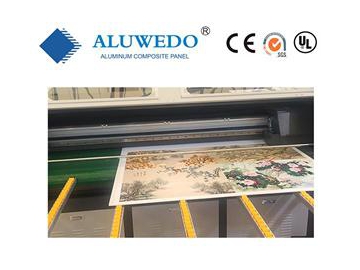

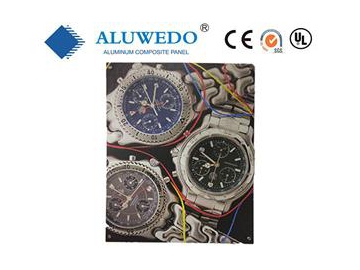

Aluwedo® digital printing aluminum composite panel is specially designed for digital UV flat printing, which is outstanding for smooth and glossy printed surface, high-definition printing, and good ink absorption, etc. This kind of panel is particularly suitable for high-end digital printing, and is an ideal for advertising material.

It is more rigid than PVC sheets and cheaper than pure aluminum sheets, as well as Acrylic sheets (PMMA).

Unique Performance

1. The digital printing Aluminum composite panel is of extremely light weight

2. Featuring excellent flatness and high flexural strength

3. Versatile processing options using routing and folding techniques

4. A variety of panel specifications for option

5. Over 95% degree of gloss

6. Easily cleaned surface

7. Resistant to fungus, moss, decay, light and UV

8. Extremely high durability

9. Recyclable

10. PE colours come with a 5 year external guarantee*.

Aluwedo Digital is a brand offering comprehensive solutions for digital printing. A specially developed coating is applied to both sides of the panel to provide vastly improved ink adhesion, far superior than standard PE coating. The high flatness of Aluwedo Digital panel allows your design to be a perfect one. Aluwedo Aluminum composite panel (ACP) can be machined after printing, with no cracks or damages on the surface.

Aluwedol ACP is also perfect for traditional screen printing as well as hand printing. After applying ink, the panel can be laminated with special films or coatings to protect the surface or to create a high-gloss effect.You can easily apply vinyl letters onto the surface in conjunction with printing.

Raw Materials

a. High strength aluminum alloy A1100, A3003

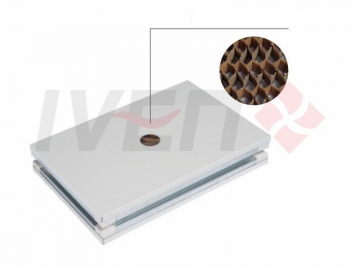

b. LDPE core

c. Surface coating: PE coating & Adhesive film from Dupont

Specifications and Dimension

a. Thickness: 2-8mm

Recommended thickness: 3mm

b. Width: 1000-2000mm

Recommended width: 1220mm, 1250mm, 1500mm, 2000mm

c. Panel length: up to 5800mm or others as required

d. Aluminum thickness: 0.12~0.3mm

e. *Custom width and length is available upon request (subject to the minimum order quantities)

| Panel thickness (mm) | 2 | 3 | 4 | 6 | 8 |

| Aluminium skin thickness (mm) | 0.21 0.30 | 0.40 | |||

| Weight (kg/m2) | 3 | 4 | 5 | 6.6 | 9 |

| Standard size (mm) | |||||

| 1000 x 2440 | * | * | |||

| 1000 x 3050 | * | * | |||

| 1220 x 2440 | * | * | * | * | * |

| 1220 x 3050 | * | ||||

| 1500 x 3050 | * | * | * | ||

| 1500 x 4050 | * | * | |||

| 2000 x 3050 | * | * | |||

| 2000 x 4050 | * | ||||

| Thickness (mm) | - 0 + 0.2 |

| Width (mm) | ± 2 |

| Length (mm) | ± 3 |

| Diagonal (mm) | ± 5 |

| Thermal expansion | 2.4mm/m at 100˚C temp difference |

| Aluminium thickness (mm) | where applicable as specified in EN485-4 |

| Paint thickness (micron) | 20 |

| Pencil hardness | >HB |

| Toughness of coating | 3T |

| Temperature resistance | -50˚C to +90˚C |

| Impact strength (kg/cm2) | 50 |

| Boiling water resistance | boiling for 2 hours without change |

| Acid resistance | immersed in 2% HC1 for 24 hours without change |

| Alkali resistance | immersed in 2% NaOH for 24 hours without change |

| Oil resistance | immersed in 20# engine oil for 24 hours without change |

| Solvent resistance | cleaned with Dimethylbenzene for 100 times without change |

| Cleaning resistance | >1000 times without change |

| Peel strength 180˚ | >5 Newton/mm |

| Panel thickness (mm) | 2 | 3 | 4 | 6 | 8 |

| Sound absorption NRC | 0.05 | ||||

| Sound reduction Rw db | 23 | 24 | 25 | 26 | 27 |

| Water absorption by volume (%) | 0.01 | ||||

| Thermal performance R- values | 0.0047 | 0.0080 | 0.0113 | 0.0180 | 0.0246 |

| Core composition | LDPE | ||||

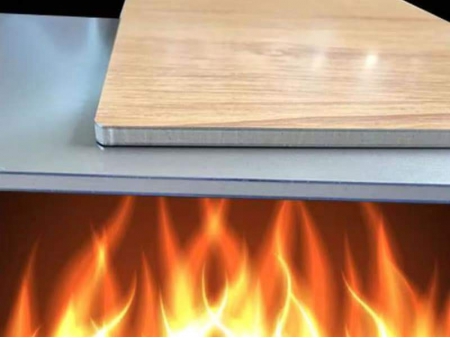

| Fire performance | Class 1 BS476 PT7 | ||||

| Class O BS476 PT6 | |||||

| Tensile strength | 149MPa | ||||

| Panel thickness (mm) | 2 | 3 | 4 | 6 | 8 |

| Sound absorption NRC | 0.05 | ||||

| Sound reduction Rw db | 23 | 24 | 25 | 26 | 27 |

| Water absorption by volume (%) | 0.01 | ||||

| Thermal performance R-values | 0.0047 | 0.0080 | 0.0113 | 0.0180 | 0.0246 |

| Core composition | LDPE | ||||

| Fire performance | Class 1 BS476 PT7 | ||||

| Class O BS476 PT6 | |||||

| Tensile strength | 149MPa | ||||

| Testing item | Standard | Result |

| Unit weight | ASTM D792 | T 3mm=4kg/m2 |

| Thermal expansion | ASTM D696 | 24-28 |

| Thermal deformation temperature | ASTM D648 | 115℃ |

| Thermal conduction | ASTM D976 | 0.102kcal/m.hr℃ |

| Flexural rigidity | ASTM D393 | 14.0*10^5 |

| Impact resistance | ASTM D732 | 1.64kgf |

| Adhesive strength | ASTM D903 | 0.77kg/mm |

| Flexural elasticity | ASTM D790 | 4030kg/mm2 |

| Shear resistance | ASTM D732 | 2.7kgf/mm2 |

| Fire propagation | ASTM E84 | qualified |

| Wind-pressure resistance | ASTM E330 | passed |

| Waterproof property | ASTM E331 | passed |