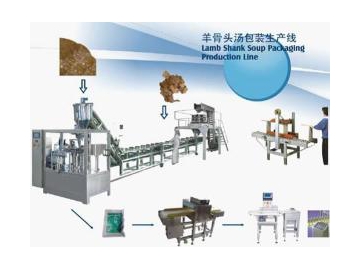

Bone and Vegetable Soup Weighing Packing

Applications of Bone and Vegetable Soup Weighing Packing

RezPack bone and vegetable soup weighing packing production line can be used to deal with retorted food, processed seafood, meat products, pasta products, pre-cooked meals, frozen food, and more.

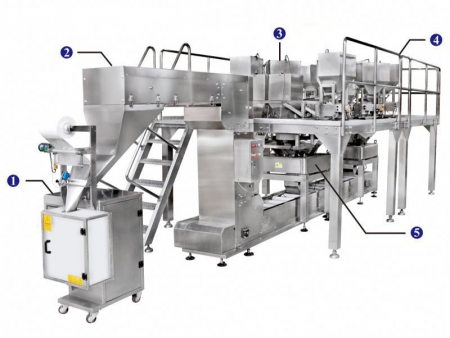

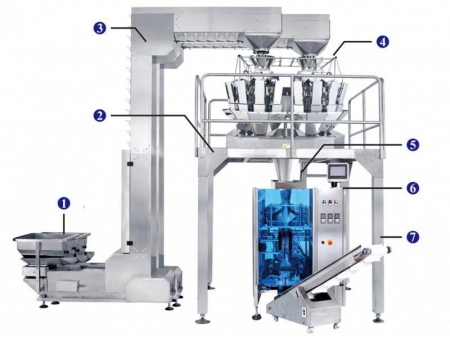

Main Features of Bone and Vegetable Soup Weighing Packing

1. A wide range of pouches: all kinds of pre-made pouches such as flat and stand-up pouches (with/ without zip).

2. Easy to operate: PLC controller, HMI system, fault indication on the touch screen.

3. Easy to adjust: only about 10 minutes to change different pouches.

4. Wide application: more than two kinds of materials can be packed in one bag.

5. Frequency control: speed can be adjusted by frequency conversion within the range.

6. High automation: The bone and vegetable soup weighing packing production line is unmanned in weighing and packing process, with auto alarm in case of failure.

7. Waterproof design: As the machine surface can be washed down, the weighing packing production line provides easy cleaning, and long service life.

Safety and Hygiene of Bone and Vegetable Soup Weighing Packing

1. RezPack bone and vegetable soup weighing packing production line provides no fill, no seal as well as auto alarm when there is no pouch/ incorrect pouch opening.

2. The bag packing machinery will automatically alarm and stop in case of inadequate air pressure.

3. The weighing packing production line, installed with safety guards with safety-switches, provides auto alarm and stop when the safety guards are opened.

4. The weighing packing machinery has hygienic structure, and the parts that touch products are made of sus304 stainless steel.

5. Designed with imported engineering plastic bearings, the bone and vegetable soup production line requires no oiling and generates no contamination.

6. The bone and vegetable soup weighing packing production line comes with oil-free vacuum pump to avoid pollution to the production environment.

| Production Line | Bone and Vegetable Soup Weighing Packing Production Line |

| Bag types | Standup bag, portable bag, zipper bag, 4-side sealing bag, 3-side sealing bag, paper bag, etc., and all kinds of compound bags |

| Bag sizes | W: 80-320mm; L:100-430mm |

| Filling range | 5-1500g |

| Packing speed | 25-30bags/min (depending on the product and filling weight) |

| Auxiliary equipment | Multi-head weigher, bucket conveyor and bowl type conveyor, working platform, filling machine |

| Package accuracy | Error ≥±1% |

| Total power | 3.6kw |

| Compressed air | ≥0.4 m3/min |